Technology

US Federal Funds Flowing: How Chipmakers Are Making The Most Of It

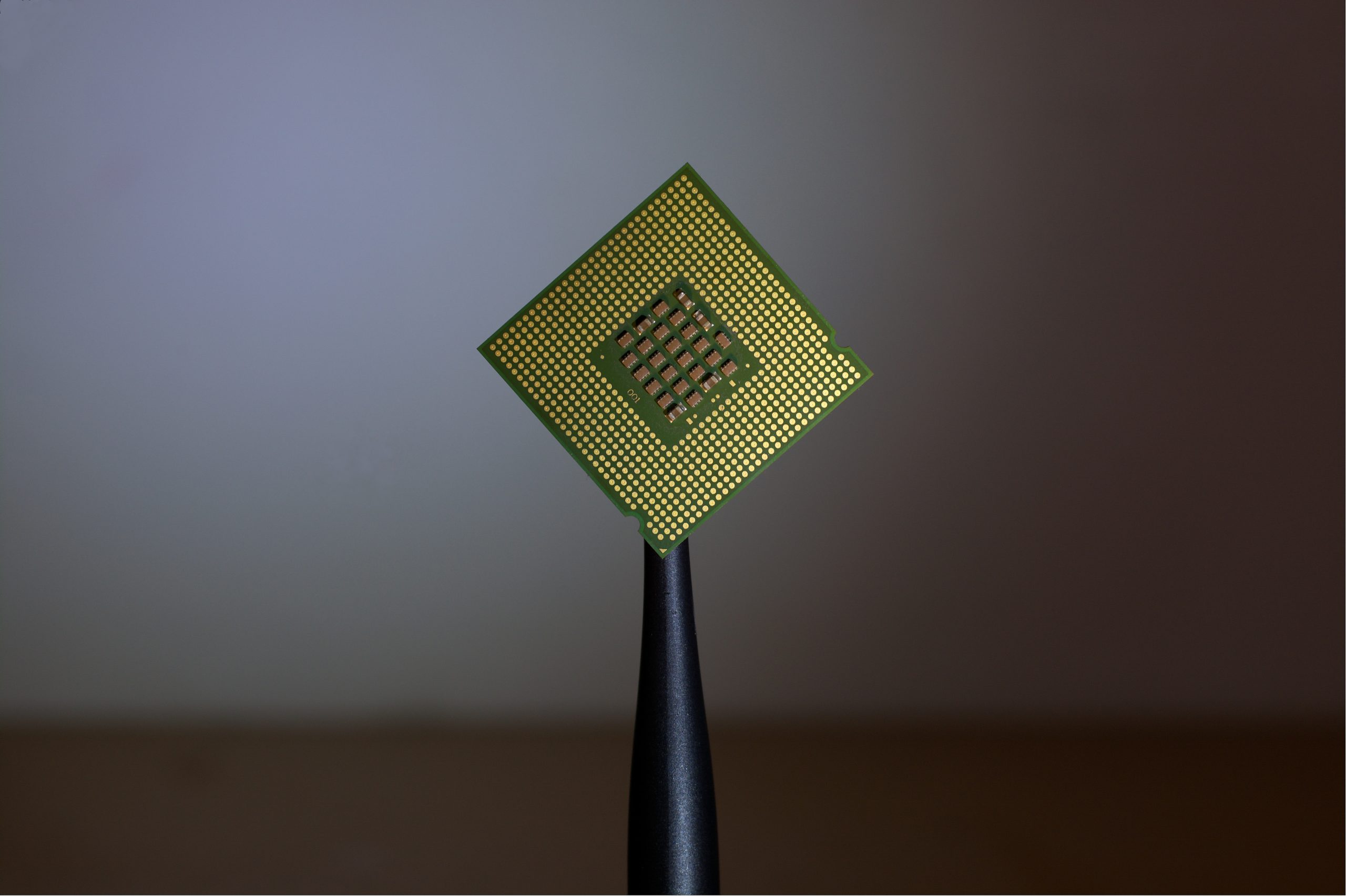

As the US continues to pour federal funds into various sectors of the economy, chipmakers are making the most of it. With billions of dollars in investments flowing into their coffers, chipmakers—and their suppliers—are continuing to invest in developing new technologies and production capacity that will remain competitive globally. In this blog post, we’ll explore how chipmakers are using these federal funds to grow their businesses and stay ahead of the competition. We’ll examine how they’re investing those funds, what benefits those investments provide, and how other companies can follow suit.

What are federal funds?

The federal funds rate is the interest rate at which depository institutions (banks and credit unions) lend reserve balances to other depository institutions overnight, on an uncollateralized basis. The federal funds rate is one of the most important prices in the U.S. economy, as it directly affects both monetary policy and borrowing costs.

In order to understand the federal funds rate, it’s necessary to first understand what reserve balances are. Reserve balances are deposits that banks keep at the Federal Reserve in order to meet their regulatory requirements. In other words, they’re like a savings account that banks use to cover any unexpected withdrawals or loan losses.

Banks are required to hold a certain percentage of their deposits as reserves, and they can choose to keep more than that if they want to. The amount of reserves a bank is required to hold depends on its size and the types of deposits it has. For example, large banks are required to hold more reserves than small banks.

When a bank has excess reserves, it can lend them out overnight to another bank that needs them. The interest rate that the lending bank charges is called the federal funds rate.

The federal funds rate is set by the market, which means that it’s determined by supply and demand for reserve balances. When there’s high demand for reserve balances (because many banks need them), the federal funds rate goes up. When there’s low demand for reserve balances (because few banks need them), the

How are chipmakers using federal funds?

The U.S. government has been awarding federal funds to chipmakers for many years now. In fact, it’s one of the main reasons why the United States has been able to maintain its leadership position in the global semiconductor industry.

Many of the world’s leading chipmakers, such as Intel, Qualcomm, and TSMC, have facilities in the United States and have received federal funds for research and development (R&D). These funds have helped these companies to develop new technologies and bring them to market quickly.

In addition to R&D, federal funds have also been used by chipmakers to build new manufacturing plants and expand existing ones. This has helped to create jobs and grow the economy.

So far, the Trump administration has proposed increasing federal funding for semiconductor R&D by $1 billion per year. This would be a big boost for the industry and would help to ensure that the United States remains at the forefront of this important technology.

What are the benefits of this for chipmakers?

As the world shifts to a more digital economy, the demand for semiconductors has exploded.

The US government has responded by investing billions of dollars in the semiconductor industry, with the goal of ensuring that American chipmakers can keep up with global demand.

This investment has already paid off, with American chipmakers reporting record sales and profits. The benefits of this government investment are twofold: first, it ensures that American chipmakers can compete in the global marketplace; and second, it helps to create high-paying jobs here at home.

It is clear that the US government’s investment in the semiconductor industry is paying off. Chipmakers are making the most of it by reporting record sales and profits. This is good news for both the economy and for American workers.

Are there any drawbacks?

Yes, there are some drawbacks to the US federal funds flowing into chipmakers. For one, it can be difficult to track where the money is going and how it’s being used. Additionally, some companies may not be using the funds in the most efficient way possible, which could lead to wastage. Finally, there is always the possibility that the government could change its mind about funding chipmakers, which could leave companies in a difficult position.

How will this impact the semiconductor industry in the long run?

The U.S. federal government is pouring money into the semiconductor industry, and chipmakers are poised to make the most of it.

The Trump administration has proposed a $1.3 billion investment in the semiconductor industry as part of its infrastructure plan. The funds would be used to support research and development, build new facilities, and create new jobs.

This is a welcome development for an industry that has been hit hard by falling demand and rising competition from China. The extra funding will help chipmakers maintain their competitive edge and continue to innovate.

In the long run, this could have a positive impact on the semiconductor industry as a whole. More investment in research and development will lead to more breakthroughs, which will benefit all players in the market. A strong U.S. semiconductor industry will also help to keep China in check, ensuring that it doesn’t become too dominant in the global market.

Conclusion

In conclusion, the US federal funds flowing into the chipmakers industries are a major boon for these businesses. With access to more resources and capital than ever before, chipmakers can make significant investments in their operations that will help them become even more competitive in the future. The extra funding will also increase research and development of innovative technologies as well as create new jobs that support local economies. Investing in chipmaker stocks is an attractive proposition for those looking to capitalize on this unique investment opportunity.

Digital Development

IP PBX System: Benefits for Remote Access and Scalability

Growing companies face one common problem. Communication becomes hard to manage as teams expand across cities and time zones. A simple phone line no longer supports daily operations. Teams require a unified system that links office personnel, remote employees, and branch sites.

An IP PBX System solves this challenge by moving business calls to the internet. It replaces old phone wiring with software based control. Calls travel through data networks instead of copper lines. This allows teams to connect from anywhere using desk phones, laptops or mobile apps.

For companies with distributed teams this setup keeps everyone on the same network. It creates one shared system for internal and external communication. When communication improves work moves faster and service quality stays steady.

Why Traditional Phone Systems Fail Growing Teams

Old phone systems were built for single offices. They depend on physical wiring and hardware boxes placed on site. When a company grows, adding new lines becomes costly and slow. Maintenance also requires technical support on location.

Distributed teams make this problem worse. Remote staff cannot easily connect to the office switchboard. Internal call transfers become difficult. Managers struggle to track calls and monitor service levels.

An IP PBX System removes these limits. Since it works through the internet teams can connect from any location. A sales agent working from home uses the same system as someone in the main office. This keeps operations unified and easier to manage.

How Internet Based Calling Works

Voice calls convert into digital signals and travel through secure networks. The system routes calls to the right extension without manual handling. This process happens within seconds and does not need extra wiring.

Centralized Communication for Distributed Teams

When teams work from different places they still need one shared communication platform. A single dashboard helps manage users extensions, call routing and reports. Managers can see activity levels and track performance in real time.

Using hosted call center software along with an IP PBX System adds more control. Calls can be recorded, monitored and routed based on team roles. Remote agents log in from anywhere while staying connected to the company network.

This central structure supports smooth collaboration. Internal calls remain free within the system. Teams can hold conference calls without extra tools. Messages and voicemails stay stored in one place. That reduces confusion and saves time each day.

Easy Scalability Without Heavy Setup

Growing companies need systems that expand quickly. Hiring new staff should not require complex hardware changes. Adding a new user in an IP PBX System usually takes only a few minutes. An admin assigns an extension and the employee logs in from any device.

Hosted call center software strengthens this benefit. Since the platform runs on remote servers companies avoid large upfront costs. There is no need for physical switchboards or bulky machines. Updates happen automatically through the provider.

Scalability allows businesses to grow without stress on communication tools. Teams stay productive even during expansion.

Remote Access and Mobility

Employees can answer calls using mobile apps or softphones. A stable internet link is enough to stay connected. This ensures that customer calls never depend on one physical office.

Better Call Control and Management

Efficient call handling improves both team productivity and customer experience. An IP PBX System offers smart call routing based on department time or agent availability. Calls reach the right person without delay.

Features such as call transfer voicemail to email and call recording support daily operations. Managers monitor call flow and identify service gaps. Reports provide clear insight into call volume and response times.

Hosted call center software adds advanced management options. Supervisors can track agent performance and maintain service standards across locations. Training becomes easier because call recordings help review real conversations.

This level of control supports faster decision making. Instead of guessing, managers rely on real data. That leads to better service quality and improved team coordination.

Cost Efficiency and Long Term Value

Communication costs often rise as businesses expand. Traditional systems charge for line rentals, hardware repair and maintenance visits. International calls also add high fees.

An IP PBX System lowers many of these expenses. Calls over the internet reduce long distance costs. Maintenance shifts to software updates instead of hardware repairs. Since the system uses existing data networks companies avoid heavy installation work.

Hosted call center software further reduces capital spending. Businesses pay based on usage or number of users. This makes budgeting easier and more predictable. Small companies benefit from enterprise level features without large investment.

Over time savings from maintenance call charges and hardware upgrades add real value. The system becomes a stable base for future growth.

Security and Reliability for Modern Teams

Business communication must remain secure and reliable. Internet based systems use encryption and secure access controls to protect call data. User permissions limit who can access settings or recordings.

Cloud based backups ensure that data remains safe even if one location faces technical issues. Teams can continue working from other sites without service interruption.

For distributed companies this reliability builds trust. Employees stay connected. Customers receive consistent support. Communication no longer depends on one office building.

Supporting Growth Without Complexity

Growing teams need structure not confusion. An IP PBX System provides that structure while keeping operations simple. It brings all calls, extensions and reports into one easy interface.

When combined with hosted call center software the system supports remote agents supervisors and managers in one shared environment. Everyone stays aligned even when working from different regions.

Clear communication supports faster response times, stronger collaboration and steady service quality. As companies expand they require tools that grow with them. A modern IP based phone system offers that stability.

Strong internal and external communication builds trust among teams and customers. For businesses planning long term growth this type of system becomes an essential part of daily operations.

Digital Development

Boldify for Facebook: Quick Bold Text in Seconds

Scroll through Facebook for just five minutes and you’ll notice something: most posts look exactly the same. Plain text blends into the feed, making it easy for users to scroll past without noticing important messages. In a crowded social media environment, visual formatting plays a major role in grabbing attention and increasing engagement. This is where Boldify, a powerful bold text generator, makes a difference. Instead of struggling with plain, unformatted posts, Boldify allows you to create eye-catching Facebook bold text instantly. In this article, you’ll learn why bold text matters, how Boldify works, and how you can use it to stand out on Facebook within seconds.

Why Bold Text Matters on Facebook (User Engagement Psychology)

Facebook is a fast-moving platform. Users scroll quickly, often stopping only when something visually stands out. Bold text works because it creates contrast. When certain words appear heavier or more prominent, the brain processes them faster.

Here’s why bold text improves engagement:

- It grabs attention in crowded feeds.

- It improves readability and scan ability.

- It highlights key messages instantly.

Bold formatting is especially powerful in:

- Facebook posts

- Comments

- Bios

- Facebook groups

If you’re building a brand or growing a personal profile, bold text strengthens your identity. It emphasizes important announcements, promotions, or calls to action, making your message harder to ignore.

The Challenge: Facebook Doesn’t Offer Built-In Bold Formatting

One of the biggest frustrations for users is that Facebook does not provide built-in bold formatting for regular posts. Unlike word processors, you cannot simply select text and click “Bold.”

That’s why many people search for:

- how to bold text on Facebook

- Facebook bold text generator

- bold letters for Facebook

Without a proper tool, users are left copying complicated codes or trying ineffective formatting tricks. This creates a clear need for a reliable and easy-to-use bold font generator.

What Is Boldify?

Boldify is an online bold text generator designed to help users create stylish bold letters instantly. Instead of modifying Facebook’s formatting, Boldify uses Unicode-based bold fonts that are fully compatible with social media platforms.

Here’s what makes Boldify simple and powerful:

- No installation required

- Works directly in your browser

- Free and instant access

- Compatible with Facebook, Instagram, Twitter, and WhatsApp

Because it uses special Unicode characters, the bold text appears naturally once pasted into Facebook posts, comments, bios, or Messenger chats. This makes Boldify a practical and beginner-friendly solution for anyone looking to create bold text online.

How Boldify Helps You Create Bold Facebook Text in Seconds

Using Boldify is straightforward and requires no technical knowledge. Here’s a simple step-by-step guide:

Step 1: Enter Your Text

Open Boldify and type your message into the input box. This could be a status update, promotional message, announcement, or bio line.

Example:

New Blog Post Live

Limited Time Offer

Join Our Community Today

Step 2: Automatic Bold Conversion

As soon as you enter your text, Boldify automatically converts it into multiple bold font styles. Within seconds, you’ll see several variations generated instantly.

Step 3: Copy and Paste to Facebook

Choose the bold style you like, click the copy button, and paste it directly into:

- Facebook posts

- Comments

- Bios

- Messenger chats

That’s it. In just a few seconds, your plain text becomes visually powerful Facebook bold text.

Key Features That Make Boldify Stand Out

There are many tools online, but Boldify offers specific advantages that make it reliable and user-friendly.

1. One-Click Copy Feature

No need to manually select text. Just click and copy instantly.

2. Multiple Bold Style Variations

Get access to different bold styles to match your tone and branding.

3. Mobile-Friendly Interface

Boldify works smoothly on smartphones, tablets, and desktops.

4. No Login Required

You don’t need to create an account. Just open and start using.

5. Fast Performance

Text conversion happens instantly without delays.

6. Clean and Simple Design

The interface is distraction-free, making it easy for beginners to use.

These features make Boldify more than just a basic bold letters generator—it becomes a practical social media enhancement tool.

Practical Ways to Use Bold Text on Facebook

Now that you know how to generate bold text, let’s explore practical ways to use it effectively.

Highlight Important Announcements

SALE TODAY ONLY

Registration Closes Tonight

Bold formatting ensures these messages get noticed quickly.

Strengthen Call-to-Actions

Instead of writing:

Join us now

Write:

JOIN US NOW

It creates urgency and clarity.

Emphasize Keywords in Posts

Highlight important parts of your message to guide the reader’s attention.

Improve Facebook Bios

Use bold text to make your profession, tagline, or brand name stand out.

Stand Out in Facebook Groups

When commenting in large groups, bold text increases visibility and improves response rates.

SEO & Branding Benefits of Using Bold Text

While bold text doesn’t directly change Facebook’s algorithm, it improves how users interact with your content.

Here’s how it benefits branding and visibility:

- Improves readability

- Encourages longer post engagement

- Strengthens personal or business branding

- Creates structured content hierarchy

- Makes posts look professional

When your content looks organized and visually appealing, users are more likely to stop scrolling and engage.

Tips for Using Bold Text Effectively

Bold text is powerful—but only when used strategically.

- Don’t overuse bold formatting.

- Highlight only key phrases or calls-to-action.

- Combine bold text with emojis carefully.

- Maintain readability and spacing.

Too much bold text can reduce its impact. The goal is to enhance clarity, not overwhelm the reader.

Conclusion

Standing out on Facebook is no longer optional—it’s necessary. Since Facebook doesn’t offer built-in bold formatting for posts, tools like Boldify provide a fast and effective solution.

Digital Development

Digital Marketing Agency in Pakistan: Strategy & Growth

In today’s rapidly evolving digital economy, businesses must go beyond traditional marketing methods to remain competitive. Consumers research brands online, compare services, read reviews, and expect personalized experiences before making purchasing decisions. Without a structured digital strategy, even the most promising businesses struggle to gain visibility and traction.

This is where a Digital marketing agency in Pakistan becomes a catalyst for strategic success. Rather than focusing on isolated campaigns, professional agencies build integrated systems that combine SEO, AI-driven insights, performance marketing, content development, and user experience optimization.

This article explores how a Digital marketing agency in Pakistan drives measurable growth by aligning strategies with modern frameworks such as SEO, GEO, AIO, SXO, AEO, and EEAT.

The Importance of Strategic Digital Marketing

Digital marketing is no longer about simply posting on social media or running paid ads. Strategic success requires:

- Clear business objectives

- Data-driven planning

- Target audience analysis

- Search intent alignment

- Multi-channel execution

- Continuous performance tracking

A Digital marketing agency in Pakistan begins by understanding a brand’s goals, industry landscape, and customer behavior. This ensures every marketing effort contributes to long-term success rather than short-term visibility spikes.

Strategy transforms marketing from an expense into a growth engine.

SEO: The Foundation of Long-Term Visibility

Search Engine Optimization (SEO) remains the cornerstone of digital success. Organic visibility provides consistent traffic without ongoing advertising costs.

Professional agencies implement:

- Comprehensive keyword research

- Search intent mapping

- Semantic keyword clustering

- Technical SEO audits

- Mobile-first optimization

- Backlink development strategies

By incorporating LSI keywords such as online marketing services, website optimization techniques, search engine ranking improvement, digital advertising solutions, and content marketing strategy, agencies strengthen topical authority without keyword stuffing.

A Digital marketing agency in Pakistan ensures that websites rank for relevant, high-intent keywords while maintaining compliance with search engine guidelines.

Organic traffic compounds over time, building a sustainable foundation for growth.

GEO: Adapting to AI-Driven Search

Search engines are increasingly powered by artificial intelligence. Generative Engine Optimization (GEO) focuses on structuring content for AI-generated summaries and contextual answers.

Agencies enhance GEO by:

- Organizing content with clear headings

- Providing in-depth, authoritative information

- Implementing structured data

- Ensuring contextual keyword relevance

This preparation ensures businesses remain visible in emerging AI-powered search environments.

A Digital marketing agency in Pakistan future-proofs digital presence by adapting to technological evolution rather than reacting to it.

AEO: Capturing High-Intent Direct Answers

Answer Engine Optimization (AEO) enhances visibility in:

- Featured snippets

- Voice search queries

- Direct answer boxes

- FAQ sections

By implementing schema markup and optimizing conversational queries, agencies increase the likelihood of appearing in high-visibility placements.

These placements improve credibility and click-through rates.

For businesses seeking strategic success, capturing direct answers strengthens both authority and traffic.

AIO: Leveraging Artificial Intelligence for Competitive Advantage

Artificial Intelligence Optimization (AIO) enhances campaign precision and efficiency.

Agencies use AI-powered tools to:

- Analyze consumer behavior patterns

- Predict high-converting audiences

- Automate ad bidding strategies

- Personalize email campaigns

- Forecast marketing performance

This data-driven approach minimizes waste and maximizes return on investment.

A Digital marketing agency in Pakistan integrates AI tools into campaigns, allowing businesses to scale efficiently while maintaining control over budgets.

SXO: Aligning Search Visibility with User Experience

High rankings mean little if visitors leave without converting. Search Experience Optimization (SXO) combines SEO with user-focused improvements.

Agencies optimize:

- Website loading speed

- Mobile responsiveness

- Navigation clarity

- Call-to-action placement

- Trust-building elements

Improved user experience leads to lower bounce rates and higher conversion rates.

Strategic success requires turning traffic into revenue, not just increasing visitor numbers.

EEAT: Establishing Authority and Trust

Search engines prioritize Experience, Expertise, Authoritativeness, and Trustworthiness (EEAT). Businesses must demonstrate credibility to rank competitively.

Agencies strengthen EEAT by:

- Publishing expert-driven content

- Highlighting industry credentials

- Securing authoritative backlinks

- Managing online reviews

- Showcasing case studies

A Digital marketing agency in Pakistan builds brand authority through consistent messaging and transparent communication.

Trust influences both search engine rankings and customer decisions.

Content Marketing: Educating and Engaging Audiences

Content remains central to digital marketing success. Informative, value-driven content attracts and nurtures potential customers.

Agencies develop:

- Blog articles

- Service pages

- Industry guides

- Case studies

- Email marketing content

Optimized content increases engagement while supporting SEO objectives.

By focusing on educational and solution-oriented content, businesses position themselves as industry leaders.

Performance Marketing for Immediate Impact

While organic strategies build gradually, performance marketing delivers quicker results.

Agencies manage:

- Pay-per-click (PPC) campaigns

- Social media advertising

- Retargeting funnels

- Conversion tracking systems

- A/B testing frameworks

Campaigns are continuously refined based on performance metrics such as return on ad spend (ROAS) and customer acquisition cost (CAC).

A Digital marketing agency in Pakistan ensures that paid campaigns align with broader strategic goals.

Data Analytics: Measuring and Refining Success

Digital marketing thrives on data.

Agencies track:

- Website traffic growth

- Keyword ranking progress

- Conversion rates

- Engagement metrics

- Revenue attribution

Continuous monitoring allows for timely optimization.

Data-driven decisions improve efficiency and support long-term scalability.

Multi-Channel Integration for Strategic Advantage

Customers interact with brands across multiple platforms. Integrated marketing ensures consistent messaging across:

- Search engines

- Social media platforms

- Email campaigns

- Content distribution networks

- Paid advertising channels

This holistic approach increases brand recall and strengthens customer trust.

A Digital marketing agency in Pakistan coordinates these channels into a cohesive strategy.

Supporting Scalability and Business Expansion

As businesses grow, marketing complexity increases.

Professional agencies support expansion through:

- Multi-location SEO strategies

- International targeting

- Advanced marketing automation

- Market-specific keyword research

Scalability requires adaptability and structured planning.

With expert guidance, businesses expand confidently without compromising efficiency.

Cost Efficiency and Risk Management

Hiring an in-house marketing team involves significant costs.

Outsourcing to a Digital marketing agency in Pakistan provides:

- Access to specialized expertise

- Advanced marketing technologies

- Reduced operational overhead

- Flexible service scaling

Agencies also minimize risks associated with algorithm updates and compliance issues.

Strategic oversight protects brand reputation while maximizing growth.

From Strategy to Sustainable Success

Driving strategic success involves:

- Comprehensive planning

- Structured implementation

- Continuous optimization

- Performance measurement

- Scalable expansion

When SEO, GEO, AIO, SXO, AEO, and EEAT frameworks work together, digital marketing becomes a sustainable growth engine.

Businesses move from reactive marketing to proactive leadership.

Conclusion

Digital success requires more than sporadic campaigns; it demands structured strategy, technological adaptation, and consistent optimization.

A Digital marketing agency in Pakistan drives strategic success by integrating SEO, AI-powered tools, performance marketing, user experience design, and authority-building strategies.

By aligning digital initiatives with modern frameworks and measurable objectives, businesses transform online presence into long-term competitive advantage.

In an increasingly digital marketplace, strategic marketing is not optional, it is essential. With the right digital partner, businesses can confidently navigate complexity and achieve sustainable growth.

From planning to performance, strategy to success a professional digital marketing agency turns vision into measurable results.

-

Business3 years ago

Cybersecurity Consulting Company SequelNet Provides Critical IT Support Services to Medical Billing Firm, Medical Optimum

-

Business3 years ago

Team Communication Software Transforms Operations at Finance Innovate

-

Business3 years ago

Project Management Tool Transforms Long Island Business

-

Business3 years ago

How Alleviate Poverty Utilized IPPBX’s All-in-One Solution to Transform Lives in New York City

-

health3 years ago

Breast Cancer: The Imperative Role of Mammograms in Screening and Early Detection

-

Sports3 years ago

Unstoppable Collaboration: D.C.’s Citi Open and Silicon Valley Classic Unite to Propel Women’s Tennis to New Heights

-

Art /Entertainment3 years ago

Embracing Renewal: Sizdabedar Celebrations Unite Iranians in New York’s Eisenhower Park

-

Finance3 years ago

The Benefits of Starting a Side Hustle for Financial Freedom