Business

Why Ring Dryers Are Perfect for Heat-Sensitive Materials

Introduction

Drying is a critical process in many industries, from pharmaceuticals to food processing. However, not all materials tolerate high heat. Heat-sensitive materials, such as delicate powders, granules, and certain chemicals, can degrade, discolor, or lose their essential properties if exposed to conventional high-temperature drying methods.

This is where ring dryers come in. Designed to handle materials gently, ring dryers offer a controlled and uniform drying environment that minimizes the risk of damage. By combining efficient heat transfer with precise temperature control, these dryers ensure that heat-sensitive materials are dried quickly without compromising quality.

In this article, we will explore why ring dryers are the ideal choice for industries dealing with delicate materials, their advantages, and their practical applications.

Understanding Heat-Sensitive Materials

Heat-sensitive materials are substances that can easily degrade, change color, or lose their chemical or physical properties when exposed to high temperatures. These materials are common in industries like pharmaceuticals, food processing, and chemicals, where maintaining quality and effectiveness is crucial.

Examples of heat-sensitive materials include:

- Pharmaceutical powders and granules

- Herbs, spices, and certain food powders

- Heat-sensitive chemicals and fine chemicals

Challenges in drying heat-sensitive materials:

- Degradation: High temperatures can break down active compounds, reducing effectiveness.

- Discoloration: Some materials may lose their natural color, affecting appearance and quality.

- Loss of properties: Physical properties like texture, solubility, or moisture content may be altered.

Because of these challenges, choosing the right drying method is essential. Traditional dryers that use high heat may not be suitable. Instead, technologies like ring dryers provide controlled, low-temperature drying that preserves the material’s integrity while ensuring efficiency.

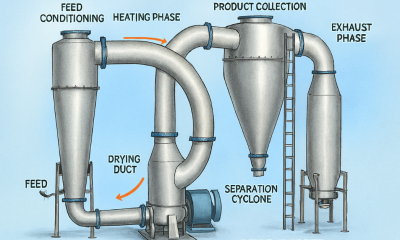

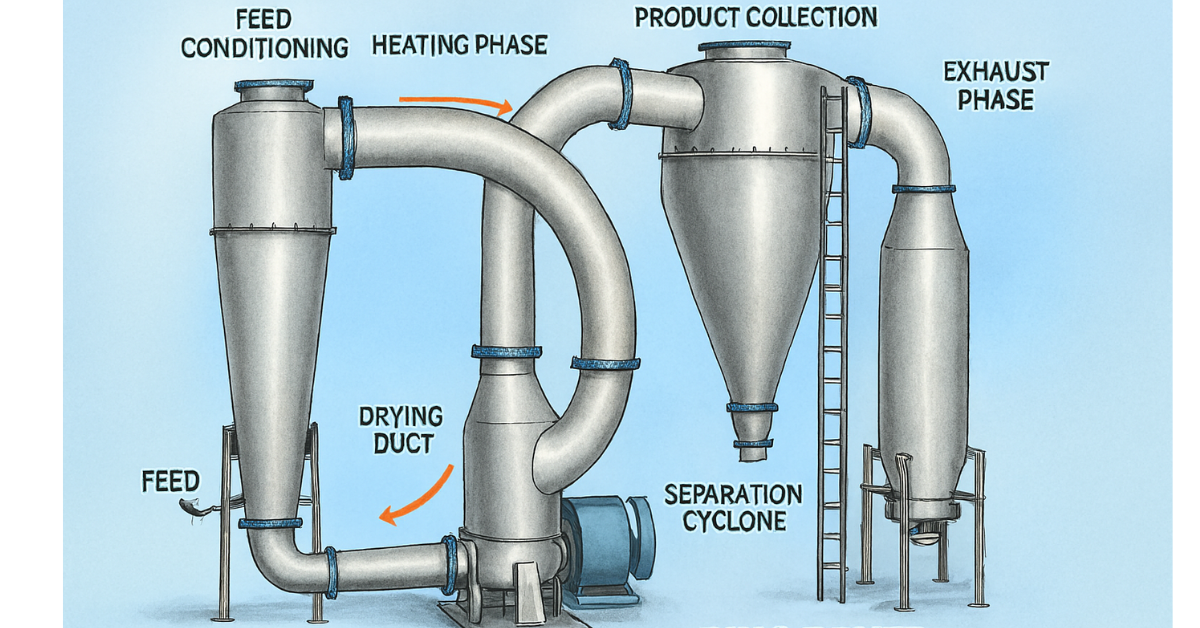

What is a Ring Dryer?

A ring dryer is an industrial drying machine specifically designed to handle materials that require gentle and controlled drying. Its unique design ensures uniform heat distribution and efficient moisture removal, making it ideal for heat-sensitive materials.

1. Design and Components

- Drying Chamber: The main cylindrical chamber where materials are dried.

- Heat Source: Provides the necessary thermal energy, often using low or moderate temperatures to protect delicate materials.

- Airflow System: Ensures even distribution of hot air around the material.

- Material Feed System: Feeds raw material into the dryer uniformly.

- Discharge System: Removes dried material efficiently without damage.

2. Working Principle

- Raw material enters the dryer through the feed system.

- Hot air circulates evenly inside the chamber, gently removing moisture.

- The design of the ring dryer allows for continuous or batch drying with minimal temperature fluctuations.

- Dried material exits through the discharge system, retaining its original properties, color, and texture.

3. Types of Ring Dryers

- Single-Ring Dryer: Suitable for small to medium-scale operations.

- Multi-Ring Dryer: Ideal for large-scale industrial drying with higher capacity.

Ring dryers stand out because they combine controlled heat, efficient airflow, and gentle handling, making them perfect for materials that cannot tolerate harsh drying conditions.

Advantages of Ring Dryers for Heat-Sensitive Materials

Ring dryers offer several benefits that make them the ideal choice for drying heat-sensitive materials. Their design and operation focus on efficiency while protecting the quality of the material.

1. Gentle Low-Temperature Drying

Ring dryers can operate at lower temperatures compared to traditional dryers, reducing the risk of degradation or discoloration in delicate materials.

2. Uniform and Controlled Drying

The airflow system ensures that hot air is evenly distributed throughout the drying chamber. This prevents hot spots and ensures consistent drying of the entire batch.

3. Reduced Risk of Material Damage

Because the drying process is controlled and gentle, the physical and chemical properties of heat-sensitive materials remain intact, preserving quality and functionality.

4. Faster Drying Without Compromising Quality

Ring dryers are efficient, allowing materials to dry quickly without the need for extremely high temperatures, which can harm sensitive products.

5. Energy Efficiency

Optimized heat and airflow management mean that ring dryers consume less energy than some other drying methods, reducing operating costs while maintaining high performance.

Applications in Industry

Ring dryers are widely used across industries where heat-sensitive materials need careful drying. Their ability to maintain product quality makes them highly versatile.

1. Pharmaceutical Industry

- Drying granules, powders, and chemical compounds without degrading active ingredients.

- Ensures uniform moisture content for consistent quality in tablets and capsules.

2. Food Industry

- Drying spices, herbs, and delicate food powders that can lose aroma, color, or nutrients at high temperatures.

- Ideal for products like tea leaves, cocoa powder, and dehydrated vegetables.

3. Chemical Industry

- Drying heat-sensitive chemicals and fine chemicals without triggering reactions or decomposition.

- Maintains purity and effectiveness of chemical compounds.

4. Other Niche Applications

- Cosmetic powders, detergents, and specialty materials that require gentle drying.

Ring dryers’ combination of efficiency and gentle handling makes them the preferred choice wherever material quality and heat sensitivity are critical.

Comparison with Other Drying Methods

When it comes to drying heat-sensitive materials, not all dryers are created equal. Ring dryers offer distinct advantages over conventional drying methods.

1. Ring Dryer vs. Rotary Dryer

- Temperature Control: Ring dryers provide precise low-temperature control, whereas rotary dryers often operate at higher temperatures, risking material degradation.

- Uniform Drying: Ring dryers ensure even airflow, avoiding hot spots; rotary dryers may cause uneven drying.

- Material Quality: Ring dryers preserve color, aroma, and chemical properties better than rotary dryers.

2. Ring Dryer vs. Fluidized Bed Dryer

- Gentleness: Ring dryers handle delicate materials more carefully, while fluidized bed dryers may subject materials to abrasive airflow.

- Energy Efficiency: Ring dryers are generally more energy-efficient for heat-sensitive products due to controlled heating and airflow.

- Application Range: Ring dryers are more versatile for powders, granules, and delicate chemicals.

3. Why Ring Dryers Are Ideal

For industries working with heat-sensitive materials, ring dryers provide the perfect balance of efficiency, quality preservation, and safety. They ensure materials are dried quickly without compromising their integrity a challenge for many other drying methods.

Factors to Consider When Using Ring Dryers

To get the best results from a ring dryer, especially when drying heat-sensitive materials, certain factors must be carefully considered:

1. Material Properties

- Know the moisture content, particle size, and sensitivity of the material.

- Delicate powders or granules require lower temperatures and gentle handling.

2. Temperature and Airflow Control

- Precise temperature settings prevent degradation or discoloration.

- Proper airflow ensures even drying and prevents hot spots.

3. Capacity and Scalability

- Choose a ring dryer that matches your production scale.

- Multi-ring systems may be needed for large-scale operations, while single-ring dryers are suitable for smaller batches.

4. Maintenance and Operation

- Regular cleaning and inspection of the drying chamber and airflow system maintain efficiency.

- Proper operation ensures consistent product quality and prolongs equipment life.

By considering these factors, industries can maximize the efficiency of ring dryers while ensuring the integrity of heat-sensitive materials.

Conclusion

Ring dryers have proven to be an ideal solution for drying heat-sensitive materials across various industries. Their ability to provide gentle, low-temperature, and uniform drying ensures that delicate powders, granules, and chemicals maintain their quality, color, and properties.

Compared to traditional dryers, ring dryers offer energy efficiency, faster drying, and reduced risk of material damage, making them a preferred choice for pharmaceutical, food, and chemical industries.

For any industry dealing with delicate or heat-sensitive products, investing in a ring dryer not only improves efficiency but also ensures that the end product retains its intended quality and effectiveness.

FAQ: Ring Dryers for Heat-Sensitive Materials

Q1. What materials can be dried in a ring dryer?

Heat-sensitive powders, granules, and chemicals.

Q2. Can ring dryers prevent material degradation?

Yes, they use controlled low temperatures to protect delicate materials.

Q3. Is the drying temperature adjustable?

Yes, it can be set according to the sensitivity of the material.

Q4. How is a ring dryer different from a rotary dryer?

It provides gentler, more uniform drying for delicate products.

Q5. Which industries commonly use ring dryers?

Pharmaceuticals, food processing, and chemical industries.

Business

Hosted Call Center Solutions: The Future of Modern Call Centers

Customer support has changed rapidly over the last few years. Businesses no longer rely only on physical offices, desk phones, or complex hardware to manage customer calls. Rising customer expectations, remote work, and growing call volumes have pushed companies to adopt more flexible solutions. This shift has led to the rise of the hosted call center solution. Instead of running calls through on-site equipment, hosted systems operate through the cloud. Agents connect through the internet and manage calls using software rather than traditional phone lines.

Hosted call centers give businesses freedom from location limits and technical burden. Teams can work from offices, home, or multiple regions without changing systems. Setup is fast, scaling is simple, and daily operations become easier to manage. As customer service becomes more critical to business success, hosted call center solutions are becoming the preferred choice for modern support teams.

The Limits of Traditional Call Center Models

Traditional call centers were built around physical infrastructure. Businesses had to invest in servers, PBX systems, desk phones, and office space. These setups required high upfront costs and regular maintenance. Any change, such as adding agents or modifying call flows, often needed technical support and caused downtime.

Scaling was another major challenge. When call volumes increased suddenly, teams struggled to keep up. Hiring new agents meant purchasing hardware and expanding office space. Remote work was difficult or impossible, limiting flexibility during emergencies or workforce changes. These limitations reduced speed, increased costs, and affected service quality. Businesses needed a system that could adapt quickly without disrupting operations. Hosted call centers filled this gap.

What Is a Hosted Call Center Solution

A hosted call center solution is a cloud-based system where all call handling happens through software managed by a service provider. Calls are routed through internet connections instead of local phone hardware. Agents log in securely using a browser or application and answer calls using headsets or softphones.

Setup is simple and does not require complex installation. Businesses can activate accounts, configure call flows, and start operations within days or even hours. Contact center software plays a central role by managing calls, customer data, recordings, and agent activity in one platform. Managers monitor performance using online dashboards. Updates, security patches, and new features are handled automatically by the provider. This removes technical pressure from internal teams and keeps systems up to date.

Why Businesses Are Moving to Hosted Systems

Flexibility is the biggest reason businesses adopt hosted call centers. Teams can add or remove agents instantly based on demand. Remote and hybrid work becomes easy to manage. Costs remain predictable because businesses usually pay based on usage or number of agents.

Hosted systems also improve reliability. Cloud infrastructure offers backups and stable connections that reduce downtime.

During seasonal peaks, marketing campaigns, or emergencies, hosted call centers handle increased traffic without system overload. Contact center software supports smart call routing, ensuring customers reach the right agent quickly. This improves response time and customer satisfaction. Businesses stay agile without investing in expensive hardware or long-term infrastructure.

How Hosted Call Centers Improve Agent Work

Agent experience directly affects customer experience. Hosted call center tools are designed to be simple and easy to use. Agents learn the system quickly and focus more on conversations instead of technical tasks. Contact center software displays customer details, call history, and notes during live calls. This gives agents confidence and reduces repeat questions.

Remote access allows flexible work schedules and improves work-life balance. Agents avoid common technical issues linked to outdated phone systems. Less stress leads to better conversations and higher performance. When agents feel supported, retention improves. This reduces hiring costs and maintains service consistency across teams.

Better Customer Experience Through Cloud Support

Customers expect fast responses and clear communication. Hosted call centers meet these expectations by reducing wait times and call drops. Calls are routed smoothly through cloud systems to available agents. Contact center software keeps records of previous interactions, allowing agents to resolve issues faster.

Customers do not need to repeat information when calling again. Even during high call volumes, hosted systems maintain stable performance. This consistency builds trust over time. A reliable support experience encourages customers to stay loyal and recommend the brand. Good customer experience becomes a competitive advantage instead of a challenge.

Scalability Without Growing Pains

Scaling used to be one of the biggest challenges in call center operations. Hosted call center solutions remove this barrier. Businesses can grow without buying new equipment or expanding office space. New agents join by creating login credentials and completing basic training.

Contact center software manages increased call traffic automatically. Performance data helps managers adjust staffing levels easily. During peak demand, resources scale up smoothly. When demand slows, businesses scale down without financial loss. This balance helps control costs while staying prepared for growth. Scalability without stress is one of the strongest advantages of hosted call centers.

The Future of Hosted Call Centers

Hosted call center solutions continue to evolve with advances in cloud technology. Contact center software now includes smarter routing, analytics, and AI-driven support features. Remote work is here to stay, and hosted systems are built for this reality.

Businesses that adopt hosted models are better prepared for future customer needs. These systems support long-term growth without locking teams into rigid structures. Call centers are no longer bound by walls, hardware, or location. Hosted call center solutions are shaping a more flexible, reliable, and efficient future for customer support.

Business

Ring Valuation: Essential Insights for Carmarthenshire Residents

Rings are among the most meaningful pieces of jewelry people own. They often represent love, commitment, heritage, and personal milestones. From engagement rings and wedding bands to antique heirlooms passed down through generations, each ring carries both emotional and financial value. Understanding that value clearly is essential, and that is where professional ring valuation plays a vital role for residents of Carmarthenshire.

This guide explains what ring valuation is, why it is important, how it works, and how to ensure you receive a reliable and accurate valuation for your jewelry.

Understanding Ring Valuation

Ring valuation is a professional assessment that determines the monetary worth of a ring at a specific point in time. The valuation is based on a detailed examination of the ring’s materials, gemstones, craftsmanship, condition, and current market trends.

The final outcome is a written valuation report that describes the ring and states its value according to the intended purpose. This document is widely used for insurance, resale, probate, and legal matters.

Why Ring Valuation Is So Important

Many people own valuable rings without fully understanding their worth. A professional valuation removes uncertainty and provides factual information.

Insurance Protection

One of the most common reasons for ring valuation is insurance. Jewelry insurers require an accurate valuation to calculate coverage. If a ring is lost, stolen, or damaged, an up-to-date valuation ensures the replacement value is correctly covered.

Fair Market Selling

When selling a ring, knowing its true value helps you avoid selling below its worth or setting unrealistic expectations. A professional valuation gives you confidence when dealing with jewelers or private buyers.

Probate and Legal Purposes

Rings are often included in estates, wills, and legal settlements. An official valuation ensures transparency, fairness, and compliance with legal requirements during probate or asset division.

Personal Knowledge and Peace of Mind

Some ring owners simply want clarity. Whether it is a gift, inheritance, or personal purchase, understanding its value brings reassurance and informed decision-making.

Rings That Typically Require Valuation

Professional valuers in Carmarthenshire commonly assess many types of rings, including:

- Engagement and wedding rings

- Diamond and gemstone rings

- Gold, platinum, and silver rings

- Antique and vintage jewelry

- Designer and branded rings

- Family heirloom rings

Each ring type has unique characteristics that influence how it is valued.

The Professional Ring Valuation Process

Ring valuation follows a structured and detailed process designed to ensure accuracy and reliability.

Visual and Structural Examination

The valuer begins by examining the ring’s overall structure. This includes assessing the design, setting, and craftsmanship to understand how the ring was made.

Gemstone Evaluation

If the ring contains gemstones, they are carefully analyzed. Factors such as size, cut, color, and clarity are assessed, as these characteristics significantly affect value.

Metal Testing and Weight Measurement

The metal type is identified and tested for purity. Gold rings, for example, may be assessed as 9ct, 14ct, or 18ct. The ring is then weighed to calculate the metal’s contribution to overall value.

Condition Assessment

The valuer checks for wear, damage, loose stones, or previous repairs. The condition of a ring can either enhance or reduce its final valuation.

Market Research

Current market prices, material values, and comparable jewelry items are reviewed. This ensures the valuation reflects realistic market conditions rather than outdated estimates.

Key Factors That Influence Ring Value

Several important factors determine the final valuation amount.

Quality of Materials

Higher-purity metals and genuine gemstones naturally increase a ring’s value. Platinum and high-carat gold generally hold higher valuations than lower-grade materials.

Gemstone Characteristics

Craftsmanship and Design

Well-crafted rings, particularly bespoke or handmade pieces, often command higher values due to the skill and time involved in their creation.

Age and Rarity

Antique and vintage rings may carry additional value if they are rare, historically significant, or in excellent condition.

Brand and Provenance

Rings from reputable designers or luxury brands often receive higher valuations due to their reputation and demand in the market.

Choosing a Reliable Ring Valuer in Carmarthenshire

Selecting the right professional is crucial. A valuation is only as accurate as the expertise behind it.

When choosing a ring valuation service in Carmarthenshire, look for qualified professionals with recognized credentials and experience in jewelry appraisal. A trustworthy valuer will provide a detailed written report and be willing to explain how the valuation was determined.

Local valuers also offer the advantage of understanding regional jewelry markets and providing convenient in-person consultations.

How Often Should You Update a Ring Valuation?

Ring values are not static. Precious metal and gemstone prices fluctuate, which can affect valuation accuracy over time.

As a general guideline:

- Update insurance valuations every two to three years

- Revalue after major market price changes

- Revalue after resizing, repairs, or resetting

Keeping valuations current ensures continued protection and accuracy.

Common Mistakes People Make

Many ring owners unintentionally make mistakes during the valuation process.

One common error is relying on outdated valuation reports. Another is assuming sentimental value translates directly into market value. While emotional significance is important personally, professional valuation focuses on material and market factors.

Using unqualified appraisers or informal opinions can also result in inaccurate valuations that are not accepted by insurers or legal institutions.

Benefits of Professional Ring Valuation

Professional ring valuation offers several clear advantages:

- Accurate, unbiased assessment

- Official documentation suitable for insurance and legal use

- Expert understanding of gemstones and metals

- Confidence in knowing the ring’s true worth

These benefits make professional valuation a smart and responsible choice.

Preparing Your Ring for Valuation

Before attending a valuation appointment, gently clean your ring to remove surface dirt. Avoid harsh cleaning methods that could damage the setting or stones.

Bring any relevant documentation, such as certificates, receipts, or previous valuations. These can help the valuer provide a more detailed and accurate report.

Final Thoughts

Ring valuation is a vital step for anyone who owns valuable jewelry. Whether your goal is insurance protection, resale, probate compliance, or personal reassurance, a professional valuation provides clarity and confidence.

With experienced professionals available locally, ring valuation in Carmarthenshire is both accessible and worthwhile. By choosing a qualified valuer and keeping valuations updated, you ensure your treasured ring is properly understood, protected, and valued for years to come.

Business

Comme des Garcons: Revolutionizing Fashion Through Innovation and Art

In the world of fashion, few names resonate with innovation, daring design, and cultural impact like Comme des Garcons. Since its inception, this avant-garde fashion house has continually challenged conventional ideas of clothing, redefining what it means to wear fashion as both an art form and a statement of individuality.

The Origins of Comme des Garcons

Founded in Tokyo in the early 1970s, Comme des Garcons emerged during a period of experimentation and global cultural shifts. Its founder, Rei Kawakubo, envisioned a brand that defied the predictable cycles of mainstream fashion. Unlike traditional labels that prioritized trends, Comme des Garcons focused on conceptual designs, often blurring the line between garment and sculpture.

Kawakubo’s philosophy emphasized clothing as an emotional and intellectual experience rather than just a functional item. Early collections shocked the fashion community with their asymmetrical cuts, deconstructed silhouettes, and unconventional textures. These bold designs established Comme des Garcons as a trailblazer in high fashion.

Comme des Garcons: Deconstruction and Innovation

One of the defining features of Comme des Garcons is its commitment to deconstruction. The brand often dismantles traditional clothing forms, challenging the norms of symmetry, proportion, and fabric usage. Jackets, dresses, and trousers from Comme des Garcons collections frequently showcase unexpected shapes, raw edges, and layered textures that create a dynamic, sculptural effect.

Innovation is not limited to design alone. Fabric selection and production techniques play a crucial role in the brand’s identity.

Global Influence and Cultural Impact

Over the decades, Comme de Garcons has transcended mere fashion to influence art, music, and pop culture. Celebrities, artists, and musicians have embraced the brand’s distinctive aesthetic, making it a symbol of individuality and nonconformity. From red carpets to music videos, Comme des Garcons has become synonymous with fearless self-expression.

The brand’s impact is also evident in collaborations with other high-profile labels. By merging avant-garde design with streetwear and commercial fashion, Comme des Garcons has created pieces that appeal to a wide range of audiences without compromising its conceptual roots. This ability to straddle the line between art and commerce has solidified its place in fashion history.

Sub-Labels and Diversification

Comme des Garcons is not a single collection but a complex ecosystem of sub-labels, each with its own identity and purpose. For example, Comme des Garcons Homme focuses on menswear with the same deconstructed and innovative approach, while Comme des Garcons Play is a more accessible line that blends playful graphics with signature design elements.

The brand also maintains specialized lines such as Comme des Garcons Black, Comme des Garcons Shirt, and seasonal experimental collections. These sub-labels allow the fashion house to explore diverse creative avenues while maintaining a cohesive overarching identity. This strategy has helped Comme des Garcons remain relevant and desirable across generations.

Fashion Shows as Art Installations

Unlike conventional runway presentations, Comme des Garcons fashion shows are often viewed as immersive art installations. Models may walk through chaotic sets, wear garments that challenge traditional silhouettes, or interact with the environment in unexpected ways. These shows are more than mere displays of clothing—they are experiences that provoke thought and engage the audience’s senses on multiple levels.

The artistic approach extends to photography, marketing, and visual merchandising. Campaigns often utilize surreal imagery, abstract concepts, and bold contrasts that reflect the brand’s philosophy of defying expectations. This comprehensive commitment to creativity ensures that Comme des Garcons remains a subject of discussion long after the runway lights fade.

Streetwear and Contemporary Appeal

While CDG is known for its high fashion experimentation, its influence on streetwear cannot be overlooked. Collaborations with sneakers, casual wear brands, and accessories have introduced its avant-garde aesthetic to a younger audience. Hoodies, t-shirts, and accessories often feature the brand’s signature heart logo, bold patterns, or asymmetrical details, making them highly coveted among streetwear enthusiasts.

This blending of avant-garde concepts with wearable streetwear has helped CDG remain both culturally relevant and commercially successful. Fans appreciate the balance between conceptual artistry and everyday practicality, creating a community that celebrates creativity without compromise.

Collectability and Investment Value

CDG pieces are not only admired for their artistic merit but also recognized as collectible items. Limited editions, collaborations, and experimental pieces often appreciate in value over time. Fashion collectors seek out vintage collections, runway exclusives, and collaborative designs, knowing that each piece represents a unique moment in fashion history.

The brand’s influence extends to museums and exhibitions, where retrospective displays celebrate its decades-long contribution to fashion innovation. These exhibitions highlight the interplay of art, design, and culture, positioning CDG as more than a fashion label—it is a movement.

Conclusion: A Legacy of Bold Creativity

In the ever-evolving world of fashion, few brands have maintained as strong and consistent an identity as Comme des Garcons. By prioritizing conceptual artistry, embracing deconstruction, and redefining traditional fashion norms, the brand has left an indelible mark on the industry. Its influence spans high fashion, streetwear, and cultural expression, making it not only a clothing label but a symbol of fearless creativity.

FAQs About Comme des Garcons

Q1: What makes CDG different from other fashion brands?

A1: The brand prioritizes conceptual design, deconstruction, and artistic innovation over mainstream trends, creating garments that challenge conventional fashion norms.

Q2: Are CDG clothes wearable for everyday life?

A2: While some collections are experimental, sub-labels like CDG Play and collaborative streetwear pieces are designed to be accessible and wearable for daily life.

Q3: How has CDG influenced streetwear?

A3: By collaborating with popular sneaker brands and creating playful, graphic-focused clothing, CDG has brought avant-garde design into mainstream streetwear culture.

Q4: Are CDG items collectible?

A4: Yes, limited editions, collaborations, and vintage pieces are highly sought after by collectors and often increase in value over time.

Q5: Does CDG have menswear collections?

A5: Absolutely. Lines such as CDG USA Homme focus on menswear, featuring the brand’s signature innovative designs and deconstructed aesthetics.

-

Business3 years ago

Cybersecurity Consulting Company SequelNet Provides Critical IT Support Services to Medical Billing Firm, Medical Optimum

-

Business3 years ago

Team Communication Software Transforms Operations at Finance Innovate

-

Business3 years ago

Project Management Tool Transforms Long Island Business

-

Business2 years ago

How Alleviate Poverty Utilized IPPBX’s All-in-One Solution to Transform Lives in New York City

-

health3 years ago

Breast Cancer: The Imperative Role of Mammograms in Screening and Early Detection

-

Sports3 years ago

Unstoppable Collaboration: D.C.’s Citi Open and Silicon Valley Classic Unite to Propel Women’s Tennis to New Heights

-

Art /Entertainment3 years ago

Embracing Renewal: Sizdabedar Celebrations Unite Iranians in New York’s Eisenhower Park

-

Finance3 years ago

The Benefits of Starting a Side Hustle for Financial Freedom