Maintenance

The Role of Smart Terminals and Terminal Management Systems

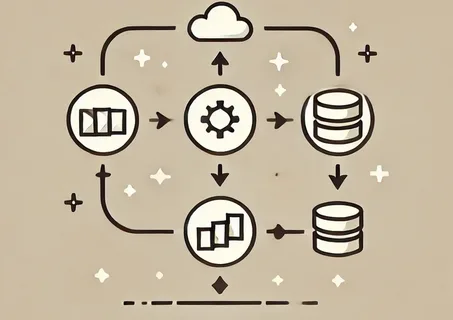

As manufacturing and energy operations become more complex and data-intensive, organizations are increasingly turning to smart terminals to improve efficiency, reliability, and safety. At the center of this transformation is the terminal management system, a digital backbone that connects equipment, people, and processes across the operational value chain. When combined with advanced analytics and integrated with a downstream commercial control system, smart terminals enable real-time decision-making and significantly reduce downtime.

This article explores how smart terminals function in manufacturing and energy sectors, the role of terminal management systems, and why their integration with downstream commercial control systems is becoming essential.

Understanding Smart Terminals

Smart terminals are digitally enabled operational hubs that manage the movement, storage, and processing of materials such as raw inputs, intermediate products, and finished goods. In manufacturing, this may involve handling chemicals, components, or bulk materials. In the energy sector, smart terminals often manage fuels, gases, lubricants, or petrochemical products.

Unlike traditional terminals that rely heavily on manual coordination, smart terminals use automation, sensors, and software platforms to monitor throughput, equipment health, inventory levels, and operational constraints in real time. The terminal management system acts as the central command layer, orchestrating these activities while ensuring compliance, safety, and efficiency.

Role of a Terminal Management System in Manufacturing

In manufacturing environments, terminals are critical choke points. Delays in material intake, internal transfers, or outbound logistics can quickly ripple across production lines.

A modern terminal management system helps manufacturers by:

-

Optimizing material flow: It schedules inbound and outbound movements to avoid congestion and idle time.

-

Enhancing visibility: Real-time dashboards show inventory levels, equipment status, and throughput performance.

-

Reducing manual intervention: Automated workflows replace paper-based processes, minimizing errors.

-

Improving maintenance planning: Predictive insights highlight equipment issues before failures occur.

By centralizing control, the terminal management system ensures that materials arrive at the right place, at the right time, and in the right quantity—supporting lean manufacturing and just-in-time production strategies.

Smart Terminals in the Energy Sector

In the energy sector, terminals play a vital role in downstream operations, including storage, blending, and distribution. The stakes are particularly high: safety risks, regulatory requirements, and volatile demand patterns require precise coordination.

Here, a terminal management system supports:

-

Safe handling of hazardous materials through automated checks, interlocks, and compliance reporting.

-

Throughput optimization by balancing loading, unloading, and storage capacity.

-

Real-time reconciliation between physical volumes and commercial records.

-

Integration with enterprise systems for planning, billing, and compliance.

Energy terminals increasingly rely on AI-enabled capabilities within the terminal management system to forecast demand, identify bottlenecks, and dynamically adjust schedules.

Integration with Downstream Commercial Control System

While operational efficiency is critical, commercial accuracy is equally important. This is where the downstream commercial control system comes into play.

A downstream commercial control system manages contracts, pricing, invoicing, nominations, and regulatory reporting. When integrated with the terminal management system, it creates a seamless bridge between physical operations and commercial execution.

Key benefits of this integration include:

-

Accurate volume and quality data: Automated data transfer reduces discrepancies between measured and billed quantities.

-

Faster reconciliation: Real-time synchronization minimizes delays in closing transactions.

-

Improved compliance: Regulatory and contractual obligations are enforced consistently across systems.

-

Enhanced profitability: Better alignment between operations and commercial decisions reduces losses and penalties.

For both manufacturing and energy companies, this integration ensures that operational excellence directly translates into commercial performance.

AI and Advanced Analytics in Smart Terminals

Smart terminals go beyond basic automation by leveraging AI and advanced analytics embedded within the terminal management system. These capabilities enable:

-

Predictive downtime reduction: Machine learning models identify early warning signs of equipment or process failures.

-

Dynamic throughput planning: AI adjusts schedules based on real-time constraints such as weather, demand shifts, or equipment availability.

-

Scenario analysis: Operators can simulate operational changes and understand their impact before execution.

When insights from AI-driven terminal management systems feed into the downstream commercial control system, organizations can make faster, more informed decisions that balance operational feasibility with commercial priorities.

Strategic Value for Manufacturing and Energy Leaders

Adopting smart terminals is not just a technology upgrade—it is a strategic move. Manufacturing and energy leaders gain:

-

Greater resilience against disruptions

-

Lower operating costs through reduced downtime

-

Higher asset utilization and throughput

-

Stronger alignment between operations and commercial outcomes

As markets become more competitive and regulatory scrutiny increases, the ability to operate terminals intelligently and transparently becomes a key differentiator.

Conclusion

Smart terminals are reshaping how manufacturing and energy companies manage complex operations. At the heart of this transformation lies the terminal management system, enabling real-time visibility, automation, and AI-driven optimization. When tightly integrated with a downstream commercial control system, organizations achieve a unified view of physical and commercial performance.

Together, these systems help reduce downtime, improve throughput, enhance safety, and ensure that operational efficiency directly supports business objectives. As digital transformation accelerates, smart terminals will continue to play a critical role in building more efficient, resilient, and profitable industrial operations.

Business

Warehouse Process Optimization for Modern Warehouse Operations

A warehouse process is essential for efficiently managing how goods move, are stored, and are shipped. Modern operations increasingly depend on warehouse management systems (WMS) to maintain accuracy, reduce errors, and track inventory in real time. By utilizing integrated systems, warehouse locations are optimized for performance, ensuring smoother logistics and faster fulfillment.

Retail brands rely heavily on retail management software to coordinate operations, and advanced inventory control systems are critical in preventing stock imbalances. With these systems in place, warehouse operations become predictable, more efficient, and faster. Additionally, an integrated order management system (OMS) can improve order fulfillment accuracy, providing a seamless flow across supply chains and increasing operational performance.

Core Components That Define an Efficient Warehouse Process

Efficient warehouse processes are supported by systems that coordinate all operations. Key components that contribute to this efficiency include:

- Warehouse Picking: Accurate picking ensures order fulfillment is on time and correct.

- Warehouse Location Mapping: Optimizing the layout for faster product movement.

- User Management: Controlled access to ensure security and productivity.

- IT System Management Tools: These tools ensure smooth operations across all systems.

Additionally, a quality management system (QMS) guarantees process consistency and reduced errors. The warehouse management system application plays a central role in standardizing processes and improving overall operational efficiency.

Warehouse Operations Driven by Digital Control Systems

In modern warehouses, automation is critical. WMS systems are designed to manage inventory movements intelligently, while enterprise systems like SAP provide robust solutions for larger environments. Digital tools in warehouse operations help strengthen:

- Inventory Control: Ensures real-time inventory visibility.

- Order Management: Enhances order fulfillment accuracy.

- Retail Operations Synchronization: Ensures that sales and inventory data align seamlessly.

These digital systems provide transparency, allowing managers to monitor stock movement in real time and make proactive decisions to maintain smooth operations.

Warehouse Process Alignment with Retail and Supply Chains

As retail businesses grow, their warehouse operations must be aligned to meet omnichannel demands. A connected retail management system integrates sales and inventory data, supporting efficient warehouse fulfillment. Key benefits include:

- Faster Warehouse Picking: Boosting efficiency and reducing order processing times.

- Controlled Warehouse Location Usage: Optimizing storage space.

- Automated Logistics Flows: Reducing manual interventions in operations.

These advancements improve overall supply chain optimization, enhancing the customer experience by ensuring faster and more reliable order fulfillment.

Warehouse Process Visibility Using Warehouse Tracking System

A transparent warehouse process relies on real-time data accuracy. A warehouse tracking system ensures instant visibility of inbound and outbound activities, improving operational control across departments. This real-time data allows managers to:

- Detect potential delays before they impact customers.

- Sync tracking data automatically with warehouse management systems.

- Strengthen inventory control to reduce discrepancies.

In turn, this leads to better planning, enhanced operational stability, and reduced risk of inventory errors.

Warehouse Process Integration with Retail Management Software

For optimal retail growth, a connected warehouse process is essential. Integration between warehouse management systems (WMS) and retail management software allows real-time updates on stock availability across multiple sales channels. This leads to:

- Faster Fulfillment: Orders are processed and dispatched more quickly.

- Improved Coordination: Synchronizing sales and warehouse data for streamlined operations.

- Enhanced Customer Satisfaction: Real-time updates improve service reliability and trust.

Through this integration, businesses can manage inventory more effectively, improve warehouse workflows, and offer better customer experiences.

Workforce Enablement and Warehouse Manager Job Requirements

People are the driving force behind warehouse success, and modern warehouse managers must possess strong digital skills to oversee operations. Key warehouse manager responsibilities today include:

- Monitoring Warehouse Operations: Ensuring daily activities run smoothly.

- Improving Process Efficiency: Identifying bottlenecks and making improvements.

- Managing IT Systems: Ensuring all technology tools work cohesively.

These skills help warehouse managers lead teams effectively, streamline processes, and ensure the consistent performance of warehouse systems.

Warehouse Process Enablement Through Dubai Warehouse Management Solutions

For businesses operating in the Middle East, Dubai warehouse management solutions offer a region-specific approach to managing logistics. These systems ensure:

- Compliance with local regulations and standards.

- Data Accuracy: Ensures reporting is reliable for better decision-making.

- Scalability: Supports growing operations, managing high volumes efficiently.

These systems enable enterprises to manage logistics operations smoothly, giving them a competitive advantage in the regional marketplace.

Technology-Driven Warehouse Process Optimization

Automation plays a critical role in warehouse process optimization. WMS systems provide real-time accuracy, while order management systems (OMS) ensure quick dispatch. Digital transformation tools contribute to:

- Streamlined Warehouse Operations: By automating routine tasks.

- Improved Retail Operations: Reducing manual effort and boosting efficiency.

- Supply Chain Optimization: Ensuring consistent and reliable fulfillment.

As a result, businesses can achieve sustainable growth by continually improving their warehouse processes.

How Ginkgo Retail Supports Smarter Warehouse Operations

Ginkgo Retail provides intelligent warehouse enablement through a platform that integrates various operational systems, improving both visibility and accuracy. The platform supports:

- Scalable Logistics Automation: Helping businesses grow without increasing operational complexity.

- Enhanced Inventory Control: Ensuring products are accurately tracked and managed.

- Aligned Retail Operations Execution: Synchronizing sales and inventory management for efficient order fulfillment.

By using Ginkgo Retail’s system, warehouses are able to optimize their processes and achieve more streamlined, cost-effective operations.

Strategic Takeaway on Warehouse Process Excellence

A modern, scalable warehouse process is key to operational success. With the right digital tools—from warehouse management systems to integrated logistics automation—businesses can streamline operations and support growth. Systems like Ginkgo Retail help ensure that warehouses remain agile, transparent, and optimized for efficiency.

FAQs on Warehouse Process and Warehouse Management

1. What is a warehouse process in logistics operations?

A warehouse process manages the storage, movement, and order fulfillment of goods.

2. How does a warehouse management system improve performance?

A WMS improves accuracy, visibility, and inventory management, leading to faster and more reliable operations.

3. Why are Dubai warehouse management solutions important?

These solutions ensure compliance with regional standards, support scalability, and enhance reporting accuracy.

4. What role does warehouse picking play in fulfillment?

Warehouse picking ensures that products are selected quickly and accurately, which is crucial for efficient order delivery.

5. How does Ginkgo Retail support warehouse process optimization?

Ginkgo Retail enhances visibility, inventory control, and logistics automation, streamlining warehouse workflows.

6. What skills define warehouse manager job requirements today?

Warehouse managers need strong digital skills, familiarity with warehouse operating systems, and the ability to improve process efficiency.

7. How does logistics automation improve warehouse operations?

Logistics automation reduces human errors, speeds up order fulfillment, and increases throughput.

8. Can Ginkgo Retail integrate with existing warehouse systems?

Yes, Ginkgo Retail integrates seamlessly with existing warehouse management platforms to optimize operations.

Business

Medical Waste Management Market: Insights and Growth Forecast

The global Medical Waste Management Market is experiencing impressive growth, with a current market size of USD 5.5 billion and a projected future value of USD 19.4 billion, representing a CAGR of 13.4%. This growth reflects both evolving trends in product usage and the increasing adoption of medical waste management solutions across regions. Roots Analysis has published an insightful report on the market, providing historical trends, current developments, and future projections to help decision-makers, investors, and industry participants better navigate the landscape.

Market Overview and Forecast

The Medical Waste Management Market has been shaped by a combination of factors, including the rise of healthcare facilities, stricter regulations on waste disposal, and technological advancements in waste treatment methods. This market is expected to continue growing due to heightened awareness of environmental sustainability and the need for safer, more efficient waste disposal processes.

Key insights from the market report include:

- Current Market Size: USD 5.5 billion

- Projected Market Size (2035): USD 19.4 billion

- Compound Annual Growth Rate (CAGR): 13.4%

The study explores how industry trends, actual performance, and new product adoptions contribute to this growth, offering a reliable data-driven foundation for market participants. Importantly, the report avoids speculative analysis, focusing instead on verified data to provide a clear, actionable understanding of market dynamics.

Market Scope and Segmentation

The market analysis includes an extensive breakdown of the key drivers, opportunities, and competitive landscape within the global medical waste management industry. It covers various facets of the market, such as:

- Types of Services Offered

- Types of Waste

- Treatment Sites

- Treatment Methods

- Categories of Waste

- Key Geographical Regions

- Key Market Players

The report also features:

- Market Size for 2025 and 2035

- CAGR Projections until 2035

- Comprehensive Segmentation Insights

- Excel Data Packs (Complimentary)

This segmentation allows stakeholders to make informed decisions based on granular insights across different categories and regions.

Key Regions and Comparative Insights

The global medical waste management market is segmented across the following regions:

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and North Africa

- Rest of the World

Each region is evaluated based on its market size, revenue performance, and contribution to the global market. Insights into regional developments and trends further help businesses tailor their strategies to specific markets.

Technological and Strategic Insights

The Roots Analysis report also provides a deep dive into the technological advancements and strategic activities that are shaping the future of the market. Topics covered include:

- Technological Advancements & R&D: Innovations in waste treatment methods, sustainable practices, and digital waste management solutions.

- Formulation & Delivery Innovations: New product formulations and efficient delivery mechanisms for waste management.

- Marketing & Distribution Strategies: Emerging trends in how medical waste management companies market and distribute their services.

- Pricing Models & Cost Structures: Analysis of pricing strategies across different service categories.

- Manufacturing & Supply Chain Trends: Key trends in the supply chain that impact the medical waste management industry.

These insights are neutral, grounded in empirical evidence, and supported by primary research, providing a comprehensive view of the market landscape.

Key Market Players

The report features profiles of major companies in the medical waste management industry, detailing their product portfolios, strategic initiatives, and recent developments. Some of the leading players include:

- ACE WASTE

- Averda

- Axil Integrated Service

- Clean Harbors

- Cleanaway Waste Management

- Curtis Bay Medical Waste Services

- E-Coli Waste Management

- GreenTech Environ Management

- Heritage Environmental Services

- Initial Medical

- Medicare

- MedPro Disposal

- REMONDIS Mendison

- Stericycle

- Trilogy MedWaste

- Triumvirate Environmental

- Veolia

- WM

For each company, the report provides insights into:

- Product portfolio and focus areas

- Operational footprint and regional presence

- Financial and strategic performance

- Recent developments, such as partnerships, market entries, and acquisitions.

Report Structure

The Roots Analysis report is structured to offer easy access to detailed insights:

- Part 1: Market Overview

- Part 2: Market Size by Regions

- Part 3: Market Revenue by Countries

- Part 4: Market Competition by Key Players

- Part 5: Company Profiles

This structure is designed to provide a clear, comprehensive view of the market, helping businesses strategize their next moves.

Why Employ Roots Analysis in the Era of Artificial Intelligence

In an era driven by technological advancements, particularly AI and machine learning, Roots Analysis remains committed to providing tailored, data-rich insights for their clients. Their robust methodology and domain expertise offer businesses the ability to make smart, informed decisions without being overwhelmed by complex data sets.

Key reasons for utilizing Roots Analysis include:

- Tailored Insights: Custom reports based on client-specific needs.

- Smart Decision Support: Insights that enable companies to make informed, strategic decisions.

- Expert Guidance: Access to the highest quality market intelligence to ensure business success.

Services Offered by Roots Analysis

Roots Analysis provides a wide array of services to support businesses in the life sciences, healthcare, and other industries:

- Consulting Services: Offering tailored insights supporting both strategic and tactical requirements.

- Subscription Services: Providing access to a library of market intelligence reports with unlimited downloads and on-demand research support.

- Bespoke Market Assessments: Custom research to track trends, dynamics, and competitive positioning in the medical waste management and other sectors.

Conclusion

For businesses involved in the Medical Waste Management industry, the Roots Analysis report is a valuable resource to help understand market dynamics, stay ahead of trends, and make informed strategic decisions. Whether you’re an investor, a company looking to expand, or a decision-maker within the industry, this report offers the insights needed to drive success in an increasingly competitive market.

Business

Bio Renewable Chemicals: Sustainability Across Industries

The bio renewable chemicals industry stands at the threshold of remarkable change. Sustainability initiatives, circular economy principles, and expanding applications across multiple sectors are driving this transformation. These chemicals now reach far beyond packaging and food production. They touch personal care products, industrial applications, and countless everyday items.

Bio renewable chemicals represent more than simple alternatives to petroleum-based products. They act as catalysts for a greener, more sustainable future. By offering eco-friendly solutions, they help industries reduce their dependence on fossil fuels. Additionally, they support global climate goals that nations worldwide have embraced.

Market Landscape: Regional Growth and Adoption

Asia Pacific Leads the Charge

Asia Pacific currently dominates the bio renewable chemicals market. Countries like China, India, and nations across Southeast Asia show remarkable growth in this sector. What drives this expansion? The packaging and food industries in these regions demand sustainable solutions at unprecedented levels.

Manufacturers across Asia Pacific increasingly recognize the value of bio-based materials. They understand that consumers want products that align with environmental values. This awareness pushes the adoption of bio renewable chemicals throughout the region’s supply chains.

North America and Europe Maintain Strong Positions

North America remains a powerful force in the bio renewable chemicals space. Innovation drives the market here, with companies constantly developing new applications. The personal care sector, food and beverage industry, and chemical manufacturers all contribute to steady demand.

Europe follows a similar pattern, though with a distinct driving force. Stringent environmental regulations push industries toward sustainable alternatives. The European Union’s circular economy initiatives create fertile ground for bio renewable chemical adoption. Traditional petrochemicals face increasing scrutiny, making way for greener options throughout the continent.

Emerging Opportunities in South and Central America

South and Central America present exciting possibilities for market growth. The personal care industry in these regions shows particular promise. Food and beverage applications also gain traction as sustainability awareness spreads.

These emerging markets offer manufacturers opportunities to establish presence before competition intensifies. Early movers stand to benefit significantly as demand continues rising.

Key Trends Shaping the Industry

Diversification of Bio-Based Chemicals

The range of bio renewable chemicals expands constantly. Glycerol, lactic acid, succinic acid, and acetone lead the way in current demand. Specialty bio-based chemicals also gain ground as industries seek tailored solutions for specific applications.

This diversification matters because it shows the versatility of bio renewable chemicals. They adapt to diverse industrial needs rather than serving only narrow purposes. Manufacturers can select precisely the right bio-based chemical for their particular requirements.

Expanding Application Areas

Bio renewable chemicals now appear in surprising places. Packaging remains a primary application, but the list grows longer each year. Food and beverage companies incorporate these chemicals into their products and packaging materials. Personal care brands highlight bio-based ingredients as selling points. The chemical industry itself uses renewable inputs for manufacturing processes. Specialty applications continue emerging as researchers discover new possibilities.

This expansion across sectors creates stability for the market. If one industry faces challenges, others continue driving demand forward.

Focus on Eco-Friendly Production

Sustainability extends beyond the chemicals themselves. Production methods now receive equal attention from environmentally conscious manufacturers. Energy-efficient technologies reduce the carbon footprint of bio renewable chemical production. Companies invest heavily in processes that align with global sustainability goals.

This focus on green manufacturing creates a virtuous cycle. Sustainable inputs combine with sustainable production methods, yielding products that truly benefit the environment throughout their lifecycle.

Growth in Bioplastics and Green Packaging

Bioplastics represent one of the most exciting frontiers for bio renewable chemicals. These materials offer durability comparable to traditional plastics while maintaining environmental benefits. Green packaging solutions gain popularity as consumers reject excessive waste.

The durability factor proves crucial here. Early bio-based materials sometimes performed poorly compared to petroleum alternatives. Today’s bio renewable chemicals match or exceed traditional options in performance while offering superior environmental profiles.

Market Forecast: Looking Toward 2031

By 2031, bio renewable chemicals will play integral roles in sustainable supply chains worldwide. Petroleum-based alternatives will continue losing ground in key sectors. The transition accelerates as production scales up and costs come down.

Lactic acid and succinic acid stand out as chemicals to watch. Their versatility makes them valuable across numerous applications. Performance in packaging and food applications particularly drives their expected dominance. Manufacturers value chemicals that perform reliably while supporting sustainability claims.

Innovation will continue shaping the market landscape. Bio-based polymers gain traction as production methods improve. Recyclable formulations address consumer concerns about waste. Strategic collaborations between chemical firms and consumer brands drive these innovations forward.

When chemical companies partner directly with the brands using their products, remarkable things happen. They develop precisely the materials brands need rather than offering generic solutions. This collaboration accelerates market expansion while ensuring products meet real-world requirements.

Recent Industry Developments

Product Innovations

Recent months brought exciting innovations in bio-based lactic acid. These developments focus on sustainable packaging and food preservation applications. The results benefit both manufacturers and consumers while reducing environmental impact.

Food preservation proves particularly interesting. Bio renewable chemicals can extend shelf life naturally, reducing food waste alongside plastic waste. This dual benefit makes them attractive to food companies seeking sustainability improvements across their operations.

Manufacturing Advancements

Production facilities for bio renewable chemicals grow increasingly sophisticated. Digital monitoring systems track every aspect of manufacturing with precision. Automated production lines enhance efficiency while maintaining quality standards.

These technological improvements serve dual purposes. They reduce the environmental footprint of production while improving economic viability. As manufacturing costs decrease, bio renewable chemicals become accessible to more industries and applications.

Strategic Industry Moves

Mergers and acquisitions reshape the bio renewable chemicals landscape. Companies strengthen global supply chains through strategic combinations. Product portfolios expand as firms acquire specialized capabilities they lacked internally.

This consolidation brings benefits to customers. Stronger companies offer more reliable supply and broader product ranges. The entire industry grows more stable as leading players establish robust positions in key markets.

Integration Across Applications

Perhaps most significantly, bio renewable chemicals now integrate deeply into consumer goods and industrial applications. They no longer serve as niche alternatives but function as primary ingredients in mainstream products.

This integration proves that bio renewable chemicals have arrived. They enhance performance while supporting sustainability goals. Manufacturers no longer sacrifice quality for environmental benefits. Instead, they gain both through thoughtful application of bio-based materials.

The Road Ahead

The bio renewable chemicals industry moves forward with remarkable momentum. Sustainability concerns that once seemed optional now drive core business decisions. Circular economy principles guide product development from conception through disposal.

For companies across packaging, food and beverage, personal care, and chemical manufacturing, bio renewable chemicals offer pathways to improvement. They reduce environmental impact without compromising performance. They support regulatory compliance while meeting consumer expectations.

The decade ahead promises continued transformation. Bio renewable chemicals will reach new applications and markets. Production methods will grow more efficient and sustainable. Strategic partnerships will accelerate innovation and adoption.

For those watching the industry, the message is clear: bio renewable chemicals have moved from alternative to essential. They power a greener future across industries worldwide.

-

Business3 years ago

Cybersecurity Consulting Company SequelNet Provides Critical IT Support Services to Medical Billing Firm, Medical Optimum

-

Business3 years ago

Team Communication Software Transforms Operations at Finance Innovate

-

Business3 years ago

Project Management Tool Transforms Long Island Business

-

Business2 years ago

How Alleviate Poverty Utilized IPPBX’s All-in-One Solution to Transform Lives in New York City

-

health3 years ago

Breast Cancer: The Imperative Role of Mammograms in Screening and Early Detection

-

Sports3 years ago

Unstoppable Collaboration: D.C.’s Citi Open and Silicon Valley Classic Unite to Propel Women’s Tennis to New Heights

-

Art /Entertainment3 years ago

Embracing Renewal: Sizdabedar Celebrations Unite Iranians in New York’s Eisenhower Park

-

Finance3 years ago

The Benefits of Starting a Side Hustle for Financial Freedom