Technology

NPR Drops Twitter Account After Elon Musk’s State-Affiliated Media Claim

On May 8, 2021, Tesla CEO Elon Musk made his debut appearance on Saturday Night Live. Following the show, Musk faced criticism from various media outlets for his performance. One of the outlets that published a critical article about Musk was National Public Radio (NPR). However, Musk responded in a different way to NPR’s article, accusing the organization of being “state-affiliated media.” This accusation has resulted in NPR dropping its Twitter account, which has drawn attention to the ongoing tension between public figures and media outlets on social media platforms.

Musk’s accusation of NPR being “state-affiliated media” came in response to the article the organization published about his performance on SNL. In the article, NPR said that Musk “struggled with the show’s comedy sketches” and “didn’t live up to the hype.” Musk, however, took offense to the criticism and accused NPR of being funded by a competitor’s government.

NPR’s decision to drop its Twitter account came as a response to Musk’s accusation. The organization stated that the decision was made in the interest of the safety and well-being of its staff. NPR added that “the public conversation on Twitter represents a unique challenge for us, as a news organization. We believe that the safety and well-being of our journalists is paramount, and we cannot in good conscience continue to participate in a platform where that safety is not guaranteed.”

NPR’s move has sparked a conversation about the role of social media platforms in shaping public discourse and the impact that public figures can have on media organizations. Social media platforms like Twitter have become a critical space for journalists to share their reporting, engage with their audiences, and hold those in power accountable for their actions. However, these platforms have also become a breeding ground for misinformation, harassment, and abuse.

Public figures like Musk have used Twitter to spread conspiracy theories and attack their critics. Their actions have raised concerns about the impact of social media on public discourse and the role that public figures play in shaping the narrative. The controversy surrounding Musk’s accusation of NPR being “state-affiliated media” is a reminder of the potential dangers of misinformation online.

As journalists, it is our responsibility to be vigilant about the impact of social media on our profession and public discourse. We must be careful not to let the speed and immediacy of social media compromise our commitment to accuracy, fairness, and impartiality. We must also be mindful of the potential for social media to be used as a tool of harassment and abuse and take steps to protect ourselves and our colleagues from its worst excesses.

In addition to these concerns, NPR’s decision to drop its Twitter account also highlights the need for social media platforms to do more to protect their users from harassment and abuse. While Twitter has taken steps to address these issues, more needs to be done to ensure that journalists and media organizations can participate in public discourse without fear of harassment or abuse.

The controversy surrounding Musk’s accusation of NPR being “state-affiliated media” is a cautionary tale about the power and potential of social media, as well as its pitfalls and dangers. It is a reminder that as journalists, we must continue to navigate this complex landscape with care, courage, and a commitment to the truth.

In conclusion, the decision by NPR to drop its Twitter account in response to Elon Musk’s accusation of “state-affiliated media” highlights the growing tension between public figures and media organizations on social media platforms. It is a reminder of the need for journalists to be vigilant about the impact of social media on public discourse and to take steps to protect themselves and their colleagues from its worst excesses. As we move forward, it is essential that we continue to hold those in power accountable, protect the safety and well

Costumer Services

How to Easily Contact Thunderbird Customer Service?

Introduction

Costumer Services

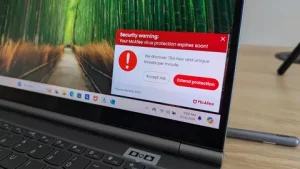

Troubleshooting McAfee Antivirus: Common Issues and Solutions

McAfee antivirus is one of the most trusted security programs used to protect devices from viruses, malware, ransomware, and online threats. It offers real-time protection, firewall security, web protection, and identity monitoring features for complete digital safety. However, many users sometimes face issues like McAfee not responding, McAfee not opening, or the software failing to run properly. When McAfee stops working, your system may become vulnerable to cyber threats.

If you are experiencing a McAfee not working error, don’t worry. In this complete troubleshooting guide, we will explain the possible reasons and provide step-by-step solutions to fix the issue. If the problem continues, you may consider contacting the official McAfee support number for professional help.

Common Reasons Why McAfee Is Not Working

Before applying any fix, it’s important to understand why McAfee may stop working. Below are the most common causes:

- Corrupted or incomplete installation

- Outdated McAfee software version

- Conflict with another antivirus program

- Windows update errors

- Malware infection blocking the antivirus

- Damaged system files

- Expired subscription

Identifying the root cause can help you apply the right solution quickly.

1. Restart Your Computer

Sometimes, temporary glitches or background processes can cause McAfee not responding issues. Restarting your computer can refresh system files and stop conflicting processes.

Steps:

- Close all open applications

- Click on Start

- Select Restart

After rebooting, try opening McAfee again. If McAfee is not opening, move to the next solution.

2. Check Your Internet Connection

McAfee requires an active internet connection for updates and license verification. A weak or unstable connection may prevent it from working properly.

- Restart your router

- Check if other websites are loading

- Try switching to a different network

Once your connection is stable, open McAfee again.

3. Update McAfee Antivirus

Running an outdated version can lead to performance issues and errors. Updating the software may fix the McAfee not responding problem.

Steps:

- Open McAfee (if accessible)

- Click on “PC Security” or “My Info”

- Select “Check for Updates”

- Install any available updates

- Restart your system

If McAfee is still not opening, continue troubleshooting.

4. Repair McAfee Installation

Corrupted installation files often cause McAfee not working errors. You can repair the software using Windows settings.

Steps to Repair:

- Press Windows + R and type

- Press Enter to open Programs and Features

- Select McAfee from the list

- Click Uninstall/Change

- Choose Repair

- Follow on-screen instructions

After completion, restart your PC and check if the issue is resolved.

5. Uninstall and Reinstall McAfee

If repair does not solve the problem, reinstalling McAfee can fix damaged or missing files.

Steps to Reinstall:

- Open Control Panel

- Click Programs > Uninstall a Program

- Select McAfee and click Uninstall

- Restart your computer

- Visit the official McAfee website

- Download the latest version

- Install and activate with your product key

This method commonly fixes McAfee not opening and startup errors.

6. Remove Conflicting Antivirus Software

Having more than one antivirus installed can cause serious software conflicts. If another security program is installed, uninstall it.

Steps:

- Open Control Panel

- Go to Programs and Features

- Uninstall any other antivirus software

- Restart your device

After removal, check whether McAfee works properly.

7. Install Pending Windows Updates

An outdated Windows system may create compatibility issues with McAfee.

Steps:

- Go to Settings

- Click Update & Security

- Select Windows Update

- Click Check for Updates

- Install available updates

- Restart your computer

Updating Windows often resolves performance and compatibility errors.

8. Run a Malware Scan

In some cases, malware can disable antivirus software. If McAfee not responding persists, use Windows Defender or Safe Mode to run a full system scan.

To scan in Safe Mode:

- Restart your computer

- Press F8 (or Shift + Restart on Windows 10/11)

- Select Safe Mode with Networking

- Run a full system scan

Remove any detected threats and restart normally.

9. Check Subscription Status

If your McAfee subscription has expired, some features may stop working.

- Log in to your McAfee account

- Check subscription status

- Renew if necessary

After renewal, reactivate the product.

When to Contact McAfee Support Number

If you have tried all the above solutions and McAfee is still not working, the issue may be technical or account-related. In such cases, contacting the official McAfee support number is recommended. Certified experts can help diagnose advanced problems such as:

- Activation errors

- License key issues

- Severe system conflicts

- Persistent McAfee not opening errors

Always make sure to contact official support channels to avoid scams.

Final Thoughts

Facing issues like McAfee not responding or McAfee not opening can be frustrating, especially when your device security is at risk. Fortunately, most McAfee not working errors can be fixed by restarting your system, updating the software, repairing installation files, or reinstalling the program.

Follow the step-by-step troubleshooting guide above to restore your antivirus protection quickly. If the problem remains unresolved, reaching out to the official McAfee support number can provide expert assistance and ensure your system stays protected.

Disclaimer:-

If you require official assistance, we recommend contacting McAfee directly through their official website or authorized customer support channels. Any reference to the “McAfee support number” in this content is intended strictly for informational purposes

Digital Development

IP PBX System: Benefits for Remote Access and Scalability

Growing companies face one common problem. Communication becomes hard to manage as teams expand across cities and time zones. A simple phone line no longer supports daily operations. Teams require a unified system that links office personnel, remote employees, and branch sites.

An IP PBX System solves this challenge by moving business calls to the internet. It replaces old phone wiring with software based control. Calls travel through data networks instead of copper lines. This allows teams to connect from anywhere using desk phones, laptops or mobile apps.

For companies with distributed teams this setup keeps everyone on the same network. It creates one shared system for internal and external communication. When communication improves work moves faster and service quality stays steady.

Why Traditional Phone Systems Fail Growing Teams

Old phone systems were built for single offices. They depend on physical wiring and hardware boxes placed on site. When a company grows, adding new lines becomes costly and slow. Maintenance also requires technical support on location.

Distributed teams make this problem worse. Remote staff cannot easily connect to the office switchboard. Internal call transfers become difficult. Managers struggle to track calls and monitor service levels.

An IP PBX System removes these limits. Since it works through the internet teams can connect from any location. A sales agent working from home uses the same system as someone in the main office. This keeps operations unified and easier to manage.

How Internet Based Calling Works

Voice calls convert into digital signals and travel through secure networks. The system routes calls to the right extension without manual handling. This process happens within seconds and does not need extra wiring.

Centralized Communication for Distributed Teams

When teams work from different places they still need one shared communication platform. A single dashboard helps manage users extensions, call routing and reports. Managers can see activity levels and track performance in real time.

Using hosted call center software along with an IP PBX System adds more control. Calls can be recorded, monitored and routed based on team roles. Remote agents log in from anywhere while staying connected to the company network.

This central structure supports smooth collaboration. Internal calls remain free within the system. Teams can hold conference calls without extra tools. Messages and voicemails stay stored in one place. That reduces confusion and saves time each day.

Easy Scalability Without Heavy Setup

Growing companies need systems that expand quickly. Hiring new staff should not require complex hardware changes. Adding a new user in an IP PBX System usually takes only a few minutes. An admin assigns an extension and the employee logs in from any device.

Hosted call center software strengthens this benefit. Since the platform runs on remote servers companies avoid large upfront costs. There is no need for physical switchboards or bulky machines. Updates happen automatically through the provider.

Scalability allows businesses to grow without stress on communication tools. Teams stay productive even during expansion.

Remote Access and Mobility

Employees can answer calls using mobile apps or softphones. A stable internet link is enough to stay connected. This ensures that customer calls never depend on one physical office.

Better Call Control and Management

Efficient call handling improves both team productivity and customer experience. An IP PBX System offers smart call routing based on department time or agent availability. Calls reach the right person without delay.

Features such as call transfer voicemail to email and call recording support daily operations. Managers monitor call flow and identify service gaps. Reports provide clear insight into call volume and response times.

Hosted call center software adds advanced management options. Supervisors can track agent performance and maintain service standards across locations. Training becomes easier because call recordings help review real conversations.

This level of control supports faster decision making. Instead of guessing, managers rely on real data. That leads to better service quality and improved team coordination.

Cost Efficiency and Long Term Value

Communication costs often rise as businesses expand. Traditional systems charge for line rentals, hardware repair and maintenance visits. International calls also add high fees.

An IP PBX System lowers many of these expenses. Calls over the internet reduce long distance costs. Maintenance shifts to software updates instead of hardware repairs. Since the system uses existing data networks companies avoid heavy installation work.

Hosted call center software further reduces capital spending. Businesses pay based on usage or number of users. This makes budgeting easier and more predictable. Small companies benefit from enterprise level features without large investment.

Over time savings from maintenance call charges and hardware upgrades add real value. The system becomes a stable base for future growth.

Security and Reliability for Modern Teams

Business communication must remain secure and reliable. Internet based systems use encryption and secure access controls to protect call data. User permissions limit who can access settings or recordings.

Cloud based backups ensure that data remains safe even if one location faces technical issues. Teams can continue working from other sites without service interruption.

For distributed companies this reliability builds trust. Employees stay connected. Customers receive consistent support. Communication no longer depends on one office building.

Supporting Growth Without Complexity

Growing teams need structure not confusion. An IP PBX System provides that structure while keeping operations simple. It brings all calls, extensions and reports into one easy interface.

When combined with hosted call center software the system supports remote agents supervisors and managers in one shared environment. Everyone stays aligned even when working from different regions.

Clear communication supports faster response times, stronger collaboration and steady service quality. As companies expand they require tools that grow with them. A modern IP based phone system offers that stability.

Strong internal and external communication builds trust among teams and customers. For businesses planning long term growth this type of system becomes an essential part of daily operations.

-

Business3 years ago

Cybersecurity Consulting Company SequelNet Provides Critical IT Support Services to Medical Billing Firm, Medical Optimum

-

Business3 years ago

Team Communication Software Transforms Operations at Finance Innovate

-

Business3 years ago

Project Management Tool Transforms Long Island Business

-

Business3 years ago

How Alleviate Poverty Utilized IPPBX’s All-in-One Solution to Transform Lives in New York City

-

health3 years ago

Breast Cancer: The Imperative Role of Mammograms in Screening and Early Detection

-

Sports3 years ago

Unstoppable Collaboration: D.C.’s Citi Open and Silicon Valley Classic Unite to Propel Women’s Tennis to New Heights

-

Art /Entertainment3 years ago

Embracing Renewal: Sizdabedar Celebrations Unite Iranians in New York’s Eisenhower Park

-

Finance3 years ago

The Benefits of Starting a Side Hustle for Financial Freedom