Autos & Vehicles

Autonomous Vehicles: What’s Next in 2025?

Introduction

The idea of autonomous vehicles—cars that can drive themselves without anyone controlling them—has been around for a long time. In 2025, this idea is closer to becoming a reality than ever. Self-driving cars could change how we travel, move around, and even think about safety on the road. Although fully autonomous cars are not everywhere yet, the technology is improving. With the help of artificial intelligence (AI), machine learning, and advanced sensors, self-driving cars are becoming safer and smarter.

In this article, we will look at what autonomous vehicles can do, the technology behind them, and what we can expect in 2025. Whether you are curious about the future of transportation or excited about new technology, this article will explain how self-driving cars are changing the way we think about traveling.

What Are Autonomous Vehicles?

Image by: Yandex.com

Autonomous vehicles, also called self-driving cars, are cars that use AI, sensors, and machine learning to drive without needing a human to take control. These cars use different technologies to see what is around them, such as LIDAR, cameras, radar, and GPS. The main purpose of autonomous vehicles is to make driving safer, reduce traffic, and make traveling easier.

These cars are tested at different levels, from Level 0 (no automation) to Level 5 (fully automated). In 2025, most cars will be somewhere between Level 3 and Level 4. This means the car can drive itself in most situations, but there may still be times when a human driver needs to help.

What Will Autonomous Vehicles Look Like in 2025?

Image by: Yandex.com

In 2025, we will see even more autonomous vehicles on the road. Here’s what we can expect from self-driving cars in the near future:

1. More Advanced AI for Safer Driving

AI will play a huge role in autonomous vehicles by making them safer. In 2025, AI systems will get better at making smart decisions while driving. As these systems learn from more data, they will be able to react faster and avoid accidents. AI will help the car recognize things like pedestrians, cyclists, and other cars, making driving safer.

2. Better Sensors for Clearer Vision

Sensors like LIDAR, radar, and cameras are important for helping self-driving cars see what is around them. By 2025, these sensors will be even better at detecting things on the road, like other cars, people, or obstacles. This will allow autonomous vehicles to drive safely even in bad weather or busy city streets.

3. Smarter Infrastructure and Connectivity

By 2025, cities and roads will be better connected with self-driving cars. 5G networks will help cars communicate with each other and with road signals, making traffic flow smoothly. Smart traffic lights could talk to autonomous vehicles, helping them avoid traffic jams. Self-driving cars will get real-time information about accidents, road conditions, or traffic, helping them avoid delays.

Challenges for Autonomous Vehicles in 2025

Image by: Yandex.com

Although autonomous vehicles hold great promise, there are still some challenges to overcome. Here are a few things that need to be fixed before self-driving cars can become common:

1. Laws and Rules for Self-Driving Cars

As self-driving cars become more common, governments will need to create new rules and laws. These laws will decide things like who is responsible if a self-driving car gets into an accident and how to make sure autonomous vehicles are safe. In 2025, we will likely see new rules that help these cars fit into our current transportation systems.

2. Trust and Public Opinion

Many people are still unsure about self-driving cars. Some may worry that these cars aren’t safe or might cause job losses, especially for people who work as drivers. To make autonomous vehicles more accepted, there will need to be more tests and demonstrations to show that self-driving cars can be trusted. Over time, as people see how well these cars work, they will likely feel more comfortable with the technology.

3. Keeping Cars Safe from Hackers

Because autonomous vehicles rely on technology and are connected to the internet, there’s a risk that they could be hacked. If a hacker takes control of a car, it could be dangerous. In 2025, car makers and governments will have to make sure that self-driving cars are protected from hackers, ensuring that passengers and data are kept safe.

The Benefits of Autonomous Vehicles in 2025

Image by: Yandex.com

Even though there are challenges, autonomous vehicles offer many benefits that will change the way we travel. Here are some of the key advantages that will be clearer in 2025:

1. Fewer Traffic Accidents

Most traffic accidents happen because of human mistakes, like speeding, distracted driving, or not following traffic laws. Autonomous vehicles will be able to drive more safely by following traffic rules precisely and reacting quickly to avoid dangers. This will help reduce traffic accidents and save lives.

2. More Accessibility

Self-driving cars will help people who can’t drive, such as the elderly or people with disabilities, get around more easily. They won’t need to rely on others or public transportation anymore. Autonomous vehicles will provide independence for people who struggle to drive themselves.

3. Better for the Environment

Many self-driving cars will be electric, which will help reduce carbon emissions and make transportation more environmentally friendly. Also, autonomous vehicles will be more efficient in how they drive, saving fuel and reducing air pollution.

4. More Efficient Travel

Because self-driving cars can talk to each other and plan their routes better, we can expect less traffic and faster travel times. Autonomous vehicles will help keep traffic moving smoothly by preventing traffic jams and avoiding accidents.

Table: Key Aspects of Autonomous Vehicles in 2025

| Aspect | Description | Impact on Society |

|---|---|---|

| Level 4 and 5 Autonomy | Self-driving cars with the ability to operate without human intervention | Changes how we drive, makes transportation safer and more efficient |

| AI-Powered Navigation | AI systems that improve driving patterns, fuel efficiency, and real-time decisions | Reduces emissions, increases efficiency, improves safety |

| Job Displacement and Creation | Impact on jobs in transportation, but new opportunities in AI, maintenance, and urban planning | Job shifts, need for re-skilling and new career paths |

| Environmental Impact | Electric autonomous vehicles that reduce emissions and fuel consumption | Contributes to cleaner cities and sustainable transportation |

Conclusion

Autonomous vehicles are set to change how we travel in 2025 and beyond. As technology improves, self-driving cars will become safer, more efficient, and easier to use. These cars will help reduce accidents, make transportation accessible to more people, and even benefit the environment. However, challenges like regulations, public trust, and cybersecurity must be addressed for these cars to become common on the roads.

Take the Next Step

Stay up-to-date on the latest advancements in autonomous vehicles. Whether you’re excited about the future of self-driving cars or just curious, the transportation industry is about to see a big transformation. Keep an eye on these developments as they shape the future of travel.

Autos & Vehicles

Caribbean Generator Set Market: Growth Prospects and Keys

The geographical and infrastructural peculiarities of the Caribbean region offer both opportunities and challenges for energy reliability. Because a few island countries are scattered across the Atlantic Ocean and the Caribbean Sea, governments and utility companies have found it difficult and expensive to introduce a fully interconnected and reliable power grid.

As a result, the high demand for reliable backup power has made generator sets an essential energy component. According to a recent study by MarkNtel Advisors. The Caribbean Generator Set Market is poised to experience robust growth in the forecast period until 2032, driven by constant power reliability concerns, the threat of natural disasters, and ongoing infrastructure development within the region.

Caribbean Generator Set Market Size and Forecast

The Caribbean Generator Set Market is estimated at USD 144.04 million in 2025 and is expected to reach USD 230 million in 2032. This anticipated growth reflects a healthy compound annual growth rate (CAGR) of approximately 8.11% during the 2026-2032 period, indicating a growing dependence on gensets for uninterrupted power supply.

Fluctuating utility grids, frequent power shortages, and a high rate of extreme weather events like hurricanes, floods, and earthquakes have all heightened the desire for reliable power. Stakeholders deploy generator sets not only in residential and commercial buildings but also in vital sectors such as healthcare, transport, telecommunication, and construction, where power cuts can significantly inconvenience critical services and disrupt economies.

Drivers of Growth

Several major forces underpin the growth of the Caribbean Generator Set Market. The region’s isolated grid systems make it difficult for utility companies to provide a constant electricity supply across all islands. Regular grid power disruptions, such as the lengthy blackouts that have affected countries like Cuba and Puerto Rico, highlight the need for businesses and homeowners to use backup power sources to keep operations running during such outages. Besides grid instability, the Caribbean’s susceptibility to natural disasters makes generator sets necessary for emergency preparedness and recovery.

Continuous infrastructure and construction work also add to market growth. For instance, large-scale projects like road construction, which regional development banks often support, require a reliable electricity supply in isolated places where grid power is limited or unavailable. In such environments, portable and sturdy generator sets—especially diesel-driven ones—are essential for providing power to equipment and tools, allowing construction and development to continue without disruptions.

Market Segments and Trends

When segmenting the Caribbean Generator Set Market by fuel type, diesel-based generator sets account for the largest share. Diesel gensets are popular because of their longevity, cost-effectiveness, and low maintenance needs. They are reliable and perform well in different environmental conditions, making them suitable for construction sites, commercial buildings, equipment rental services, and various industries across the region.

Although diesel is the major fuel type, interest is growing in potential alternatives, including natural gas, gasoline, hybrid, and other emerging technologies. As sustainability and emission concerns become more prominent, hybrid generator sets that combine traditional fuel with battery systems or renewable energy integration could gain popularity in some segments, especially where environmental standards are evolving and governments implement clean energy policies.

End-User Demand Dynamics

The Caribbean has a large number of end users of generator sets. Hospitality, retail, schools and data centers in the business world use backup power to maintain operations of their businesses and protect business critical functions. Electrical power is needed at all times by healthcare facilities especially to support life-saving medical equipment and services to patients. The transport and government sectors are other essential users of generator sets particularly in the disaster response and the operations of the social security in the event of grid outage.

Industrial uses such as manufacturing plants, assembly plants, mines, and oil and gas facilities are also a source of demand of generator sets. These are remote facilities that usually have restricted grid power supply and therefore gensets become very necessary in ensuring the facility is productive and operating at its usual pace. Moreover, equipment rental firms are increasingly gaining prominence in the provision of temporary power to companies and individuals who have a one-time demand of electricity.

Competitive Landscape

The Caribbean Generator Set Market has a competitive and varied environment of players on a global and regional level. As per the report prepared by the MarkNtel Advisors, the following companies target this market:

- Caterpillar Inc.

- Cummins Inc.

- Generac

- Discovery Energy, LLC (Rehlko)

- AGG Power Group

- INGCO

- PowerLink

- Mitsubishi Heavy industries.

- Genesal Energy

- Forest City Generators

- Atlas Copco

- Others

These companies introduce both the worldwide brand reputation and local experience, which provide a broad mix of different genset models in various types of fuel, power output, and applications to suit the needs of the Caribbean market. Some of the most famous ones are Caterpillar and Cummins with their high reliability and large networks of service. Other companies such as Generac and AGG Power Group are also playing a role in diversified product offerings which serve residential, commercial as well as industrial markets.

The Future Strategic Opportunities.

The Caribbean Generator Set Market is facing a number of strategic opportunities that can be exploited by the stakeholders. The continuous growth of the commercial infrastructure, increase in the energy consumption by the residential and industrial sectors and the growth in investment in disaster resistant energy systems are opening up new avenues of growth. The manufacturers and suppliers of generator sets may also be able to increase market penetration by creating localized service networks, tailoring financing options. Also developing product innovations to increase fuel efficiency and decrease operation costs.

With the region looking into cleaner energy options and hybrid power brands, market participants could also look into partnering or integrating technologies, fusing genset reliability and renewable energy power sources and energy storage solutions.

Autos & Vehicles

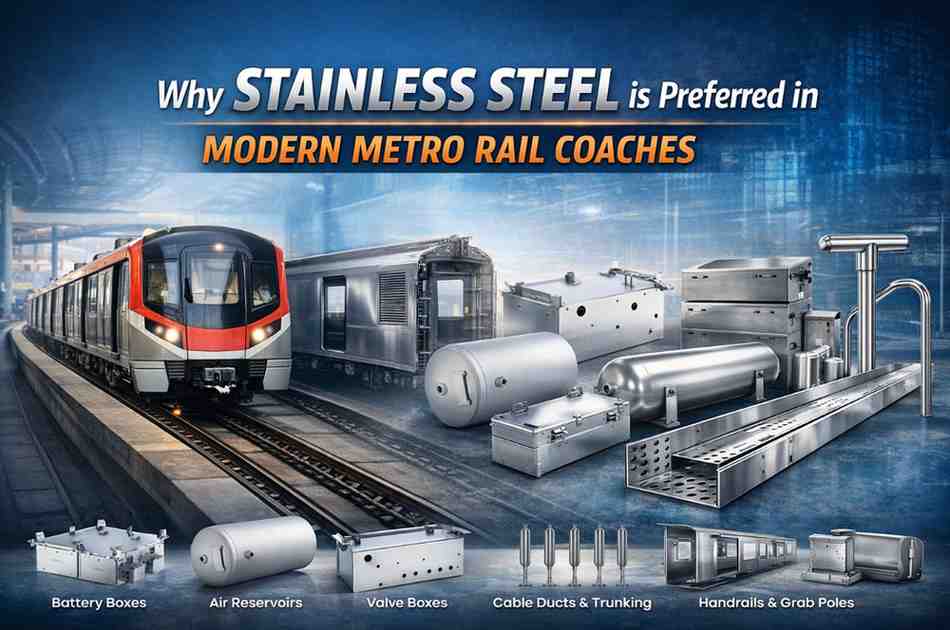

Stainless Steel: The Key Material for Modern Metro Rail Coaches

Metro rail systems are expanding rapidly across major cities in India and across the globe. With rising urban populations, increasing passenger density, and growing expectations for sustainable infrastructure, metro coaches must be built using materials that offer durability, safety, and long-term value. The material ensures long-term reliability without adding unnecessary weight.

From underground tunnels exposed to moisture to elevated corridors facing pollution and extreme weather, rolling stock materials must withstand harsh operating conditions every day. In this environment, stainless steel has emerged as the preferred material for modern metro rail coaches. It offers the right combination of structural strength, corrosion resistance, safety performance, and lifecycle efficiency.

This blog explains why stainless steel metro coaches dominate modern rail manufacturing and why stainless steel railway components are widely used in today’s metro systems.

Evolution of Materials in Metro Coach Manufacturing

Mild Steel in Early Railway Coaches

In the early years of rail transport, mild steel was commonly used for coach construction. While it provided reasonable structural strength, it required frequent maintenance due to rust and corrosion. Regular repainting and structural repairs increased long-term operational costs.

Aluminum as a Lightweight Alternative

To reduce overall train weight and improve energy efficiency, aluminum was later introduced in rail coach manufacturing. Although aluminum reduced mass, it has certain limitations:

- Lower fatigue strength under repetitive loading

- Higher susceptibility to dents and deformation

- Limited performance under high-impact stress

Transition to Stainless Steel

Over time, manufacturers began adopting stainless steel metro coaches because of their superior mechanical properties and durability. Stainless steel combines strength, corrosion resistance, and long service life, making it more suitable for demanding metro environments.

High Strength-to-Weight Ratio

One of the main reasons stainless steel is preferred in metro rail manufacturing is its excellent strength-to-weight ratio. Advanced stainless steel grades such as 200 series, 300 series, 400 series, and duplex variants provide:

- High tensile strength

- Strong fatigue resistance

- Structural stability

- Reduced thickness without compromising safety

This allows engineers to design lightweight yet strong metro coach bodies capable of handling high passenger density and operational stress.

Structural elements such as underframes, side walls, and roof panels benefit significantly from stainless steel’s strength characteristics. The substance guarantees enduring dependability while not increasing unnecessary heft.

Superior Corrosion Resistance

Metro trains operate in challenging environments that can accelerate material degradation. These include:

- Underground tunnels with high humidity

- Coastal regions with salt exposure

- Industrial zones with airborne pollutants

- Frequent temperature variations

Stainless steel contains chromium, which forms a protective passive layer on the surface. This layer prevents rust and corrosion even under harsh environmental conditions.

Corrosion-resistant railway materials such as stainless steel significantly reduce maintenance requirements. This improves operational efficiency and ensures long-lasting metro coach durability.

Long Service Life and Lower Maintenance

Metro systems are long-term infrastructure investments. Coaches are expected to operate efficiently for several decades. Lifecycle cost becomes more important than initial material cost.

Stainless steel offers:

- Minimal repainting requirements

- Reduced corrosion-related repairs

- Extended service intervals

- Lower replacement frequency

Because stainless steel retains its structural integrity over time, metro operators benefit from reduced downtime and maintenance expenses. Over a 30–40 year operational period, stainless steel metro coaches often prove more economical than alternative materials.

Fire Resistance and Passenger Safety

Safety is a critical priority in metro rail systems. Materials used in coach construction must comply with strict fire safety and structural standards.

Stainless steel provides:

- High melting point

- Resistance to flame spread

- Structural stability during high-temperature exposure

In the event of fire incidents, stainless steel maintains its strength longer than many other materials. This enhances passenger protection and supports evacuation procedures.

Fire-resistant railway materials are essential for regulatory approvals, and stainless steel consistently meets these requirements.

Sustainability and Recyclability

Sustainability is increasingly influencing infrastructure decisions. Metro authorities aim to reduce environmental impact and improve material efficiency.

Stainless steel supports sustainable metro infrastructure in several ways:

- It is 100% recyclable

- It has an extended service life

- It reduces material replacement frequency

- It supports environmentally responsible manufacturing practices

At the end of a metro coach’s life cycle, stainless steel components can be recycled without losing their essential properties. This makes stainless steel an environmentally responsible choice for long-term urban transit systems.

Applications of Stainless Steel in Metro Coaches

Stainless steel is widely used in both structural and functional components of metro coaches.

Structural Shell Components

- Side walls

- Roof panels

- Underframes

- Car body shells

Enclosures and Protective Housing

Metro coaches contain several mechanical and electrical systems that require protection, including:

- Battery boxes

- Air reservoirs

- Valve boxes

Stainless steel enclosures protect these systems from corrosion, physical damage, and environmental exposure.

Interior Fittings and Safety Elements

Passenger safety and comfort rely on durable interior fittings such as:

- Handrails

- Grab poles

- Cable ducts

- Seating frames

Stainless steel interior components resist wear caused by continuous passenger use. They also maintain a clean and professional finish over time.

Stainless Steel vs Aluminum in Metro Coaches

When comparing stainless steel and aluminum in metro coach construction, several factors must be evaluated.

Structural Strength

Stainless steel generally offers higher tensile and fatigue strength, making it more suitable for structural applications subject to repeated loading.

Corrosion Performance

Both materials resist corrosion, but stainless steel performs better in polluted, humid, and coastal environments without requiring protective coatings.

Lifecycle Cost

Although aluminum reduces weight, stainless steel often provides better long-term value due to lower maintenance and higher durability.

Maintenance Requirements

Stainless steel requires minimal repainting and surface treatment, reducing operational downtime.

For these reasons, many metro manufacturers prefer stainless steel for critical structural and safety components.

Importance of Certifications and Standards

Metro rail manufacturing operates under strict global standards to ensure safety and reliability.

Key certifications include:

- IRIS (International Railway Industry Standard)

- EN15085 welding certification

- ISO quality management systems

These certifications ensure consistent quality, proper welding procedures, material traceability, and structural integrity. Stainless steel railway components manufactured under certified systems provide greater confidence to metro authorities and rolling stock manufacturers.

Role of Advanced Fabrication and Testing

Precision engineering is essential in metro coach manufacturing. Stainless steel fabrication involves advanced processes such as:

- Robotic welding

- Fiber laser cutting

- CNC bending and forming

- Non-destructive testing

Each component undergoes thorough testing for:

- Tensile strength

- Corrosion resistance

- Weld integrity

- Dimensional accuracy

Advanced manufacturing capabilities ensure that stainless steel metro components perform reliably under real-world conditions.

Choosing the Right Stainless Steel Metro Component Manufacturer

Material selection alone does not guarantee performance. The expertise and capability of the manufacturer play a critical role in ensuring compliance and reliability.

When selecting a stainless steel metro component manufacturer, decision-makers should evaluate:

- IRIS certification

- EN15085 welding compliance

- Production capacity

- In-house testing facilities

- Experience in metro and railway projects

- Capability to work with multiple stainless steel grades

Jindal Mobility specializes in stainless steel components for metro systems. With experience in manufacturing structural shells, enclosures, and interior fittings, the company supports metro projects from design and prototyping to mass production. Its certified processes, integrated facilities, and strong quality control systems make it a reliable partner for metro OEMs and system integrators.

Partnering with a qualified manufacturer reduces supply chain risks, ensures consistent quality, and supports the long-term success of metro projects.

Conclusion

Modern metro rail systems demand materials that deliver durability, safety, efficiency, and sustainability. Stainless steel meets these requirements effectively.

Its high strength-to-weight ratio, excellent corrosion resistance, long lifecycle performance, fire safety characteristics, and recyclability make it the preferred material for modern metro rail coaches.

From structural shells and underframes to interior fittings and protective enclosures, stainless steel railway components form the backbone of reliable urban transit systems. When combined with certified manufacturing processes and advanced fabrication technology, stainless steel enables metro networks to operate safely and efficiently for decades.

As metro infrastructure continues to expand worldwide, stainless steel will remain central to the future of rolling stock material innovation.

Autos & Vehicles

What to Expect at an Auto Body Shop in Fort Lauderdale

An auto body shop visit can be more confusing than you may think, especially after your car is involved in an accident. Knowing what happens during the visit can ease anxiety and streamline the auto repair process at the auto body shop Ft Lauderdale FL. It also helps you stay informed while your car is getting repaired. That’s why we cover the whole process step-by-step in the following points. Let’s not waste any more time and dive into the blog.

What to Expect During an Auto Shop Visit

Here, we cover what happens during an auto repair and when you visit an auto shop. Keep reading with us for a better understanding.

Scheduling and Checking In

Auto shops generally prefer customers to schedule appointments, especially for significant repair work. You should know your car’s make, model, and issue. After learning these things, the shop can prepare accordingly and assign the right technician for your project. Early appointment slots reduce wait times. Some shops also offer rental vehicles or loaners if needed. When you arrive at the auto shop, check in at the front desk and provide paperwork like insurance details, DL, and vehicle registration.

Meeting the Technician

The assigned technician asks about the issues in your car and inspects it. Tell them everything, whether they are unusual noises, vibrations, or changes in performance. The more details you share with the technician, the better. Then, they explain the issues and show the areas of concern to you. The technician may also take photos of the damage if you have filed an insurance claim.

Reviewing Repair Options

After assessment, they offer repair options, ranging from quick fixes to comprehensive solutions. The technician will also discuss the use of OEM or aftermarket parts. OEM parts are long-lasting, compatible parts for your car, while aftermarket parts can save money but vary in reliability. After this, you receive a written estimate, including parts, labor, and extra charges, if there are any.

Explaining the Repair Process

The shop will thoroughly explain the repair process to you. Renowned auto shops update customers on each phase of the repair process via phone, email, or even an online portal. Each stage is performed with quality control in mind, and technicians review their work to ensure the car is restored to its pre-accident condition.

Managing the Repair Timeline

Timelines differ depending on factors like the extent of the damage, the availability of parts, and the workload at the shop. You should ask the shop about how long the repair would take. Trustworthy shops update you if there are delays due to unforeseen issues. Quality repairs take time, so don’t rush the job. Reputable shops aim to deliver results, not to complete the job ASAP.

Tracking Progress

You can ask the shop if they provide progress updates. Some auto body shops send digital updates and photos, so you know how your car is doing without coming to the shop. These services add peace of mind and reinforce accountability.

Handling Unexpected Delays

Delays can originate from various issues, such as part shortages, extra hidden damage, or shop workload. Reputable auto body shops keep customers notified about such setbacks. Proactive updates and clear explanations show the shop appreciates your time and trust. Some shops even offer rental car discounts or other assistance if repairs take longer than expected.

Working with Insurance

Auto shops are typically familiar with the insurance claim procedure and help you navigate it. They will help with paperwork, document the damage, and communicate with the insurance adjuster on your behalf. It minimizes stress and speeds up claim processing.

Getting Your Claim Approved

Auto repairs cannot be started without the insurance company approving the estimated repair costs. Your auto shop will act as a liaison, providing thorough documentation and photographs to support your claim, helping you obtain approval. If the insurance adjuster disputes the estimate, the shop may negotiate on your behalf, saving you time and frustration. You should stay in touch with the insurer and the shop and get regular updates. It helps move the claim process smoothly and keeps everything aligned between the two parties.

Coordinating Payment and Insurance

Some customers pay out-of-pocket, while others use insurance. Either way, a trustworthy shop will always walk you through costs and deductibles. If you are using insurance to pay for repairs, confirm what is covered, as policies differ widely. Some shops offer financing and payment plans for unexpected expenses. A good shop maintains transparency in billing, too, but you should ask about available options.

By now, you must have learned what happens during an auto shop visit. When your car needs repair, you should always go to a reputable auto shop. If you are looking for one, we are Superior Exotics Color and Paint, a reliable auto body shop Ft Lauderdale FL. We have high-quality parts, top-of-the-line products, a state-of-the-art facility, and a dedicated team of technicians. Contact us to book your auto repair service, or come to our shop.

-

Business3 years ago

Cybersecurity Consulting Company SequelNet Provides Critical IT Support Services to Medical Billing Firm, Medical Optimum

-

Business3 years ago

Team Communication Software Transforms Operations at Finance Innovate

-

Business3 years ago

Project Management Tool Transforms Long Island Business

-

Business2 years ago

How Alleviate Poverty Utilized IPPBX’s All-in-One Solution to Transform Lives in New York City

-

health3 years ago

Breast Cancer: The Imperative Role of Mammograms in Screening and Early Detection

-

Sports3 years ago

Unstoppable Collaboration: D.C.’s Citi Open and Silicon Valley Classic Unite to Propel Women’s Tennis to New Heights

-

Art /Entertainment3 years ago

Embracing Renewal: Sizdabedar Celebrations Unite Iranians in New York’s Eisenhower Park

-

Finance3 years ago

The Benefits of Starting a Side Hustle for Financial Freedom